High-precision Coating Equipment

RS Coater™ Single-wafer Coating Equipment

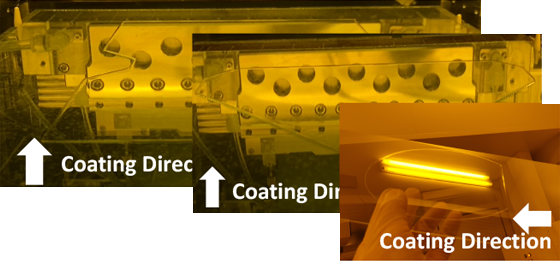

Featuring an adjustable-width die head, the RS Coater can handle a wide variety of substrate shapes.

Features

- Original adjustable-width head for use with a variety of coating shapes.

- Patterned coating for reduced material loss.

- The original adjustable-width head for improved coating responsiveness.

- High discharge stability at the start and end of coating.

- Sharp corner edge coating.

(Support for rounded corners using the adjustable-width head) - No need for tricky correction recipes at start or end of coating.

- Handles high-viscosity liquids and thick coating.

(No need for overcoating even with thicknesses up to several hundred micrometers) - Highly flexible single-wafer system for roll-to-roll prototyping and medium-volume production.

Coats even unusual shapes!

Coating is even possible for the following shapes!

Superior coating thickness precision

Thin coating of low-viscosity liquids is now possible

for full-surface coating applications!

Capable of handling a wide variety of applications!

| RS Coater |

Slit coater |

Inkjet | Dispenser | Screen printing |

|

|---|---|---|---|---|---|

| Irregular shape coating |

● | ● | ● | ● | |

| High-viscosity liquid coating |

● | ● | ● | ● | |

| Continuous coating |

● | ● | ● | ● | |

| Thick coating |

● | ● | ● | ||

| High-speed coating |

● | ● |

※Comparison of products by application

Specifications

- Coating width: 300 mm max. (wide nozzle currently under development)

- Viscosity: Several mPa·s (cps) to 50,000 mPa·s (cps)

- Coating thickness: Up to 1,000 μm/Wet

- Coating thickness precision: ±3 to 5% or less

- Liquid utilization efficiency: 90% or more

※Contact us to discuss coating conditions to meet desired viscosities.

※Coating in environments with low dew points also supported.

Product introduction video

Operation explanation video

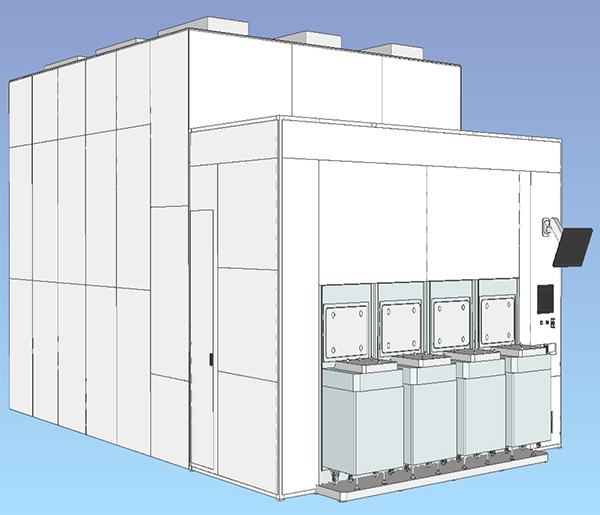

System solutions

Let us help you find a systems solution that’s right for you.

Process flow example:

Load port (EFEM) → Alignment → Coater → Bake → CP → Load port (EFEM)

Drying process option: Vacuum drying device (VCD)

Baking process option: Combination with Cure Oven, etc. possible