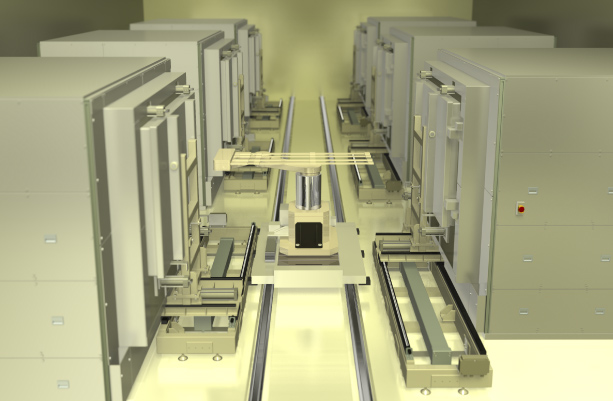

Heat Treatment Equipment

Clean Oven System

This clean oven system incorporates our newly developed, proprietary special heat-resistant filter!

Contributes to enhanced productivity thanks to a space-efficient design tailored for mass production!

Because HEPA filters are not used, a cleanliness class equivalent to that of an IR oven is achieved (class10).

This unit also significantly outperforms conventional hot air ovens in terms of heating/heat-up capacity and uniformity of temperature.

Because it relies on hot air circulation, the amount of N2 and electricity used is half that of an IR oven, thus providing outstanding energy efficiency. Also, the entire furnace chamber is heated, thus preventing condensate and sublimate from adhering to the furnace chamber walls and, thus, ensuring no reduction in operating rate due to periodic cleaning.

■Principal Applications

PI curing (e.g., flexible OLED), annealing, dehydrogenation or other treatments for TFT, baking for frit sealing (OLED) or other glass

■Unit Specifications

- Substrate size: G2.5 – G8.5

- Heating method: Convection-type (heated air circulation-type)

- Maximum temperature: Max.550°C

- Temperature precision: ΔT = ≤ 9°C

- Heat-up/cool-down rate: Up rate = 7°C/min Down rate = -7°C/min (Ave.)

- Cleanliness class: Class10

- Atmosphere: Air or N2 gas (pure N2)

- Furnace interior O2 concentration: ≤ 10ppm (when using pure N2)