High-precision Coating and Drying Equipment

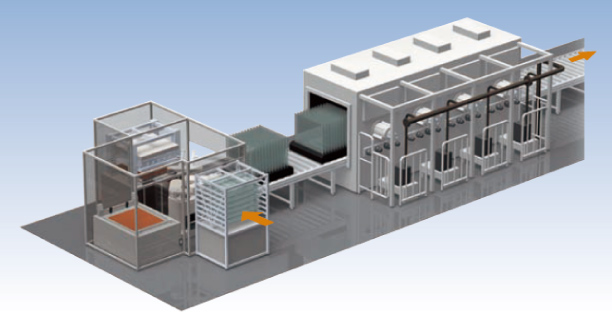

High Viscosity Coater System (PI)

A system which performs coating, drying and baking of pastes and other comparatively high viscosity solutions onto glass and plastic substrates.

Thanks to its incorporation of Chugai Ro’s many years of experience and achievements with high-viscosity coating, this system can perform mass production of the industry’s thinnest (5.8um) polymide film coatings for use with flexible OLED.

■Principal Applications

PI film for flexible displays, FOPLP, OCR, etc.

■Unit Specifications

*Unit configuration and specifications for typical PI film for flexible displays.

- Coater

Coating size: Everything from G1 – G9 (for coater alone, max. width of 2,600mm)

Coating speed: ≤ 100mm/sec

Coating viscosity: 1,000 – 100,000 cps - Wet cleaning

Typical example: (1) IN C/V → (2) Dry cleaning (E-UV or AP Plasma) → (3) Roller brush → (4) 2 fluids → (5) HPMJ → (6) Final rinse → (7) Air knife → (8) OUT C/V - Dehydration Bake unit (HP/CP)

HP working temperature: 50 – 150°C

CP working temperature: 23°C - Heating decompression drier (H-VCD)

Working temperature: 30 – 150°C