Related Contract Testing

FLOLIA® Coater System

Testing Unit

FLOLIA® Coater System

Testing Unit Installation Site

Chugai Ro Sakai Works (Sakai City, Osaka Prefecture)

Unit Specifications

- Maximum substrate size: 400 mmW × 500 mmL

- Coating thickness: ≥ 1 μm wet (100 nm – 1,000 μm dry)

- Coating viscosity: 0.001 – 100 Pa∙s (1 – 100,000 cps)

- Coating speed: ≤ 200 mm/sec

- Installation environment: Class 10

System Process

- Pre-coating substrate cleaning apparatus: E-UV, Wet cleaning

- Coater: SLIT COATER

- Reduced pressure drying apparatus: Heat treatment process-capable

- Hot plate

- Clean oven: N2 atmosphere-compatible, Max. 500℃

- Film defect inspection apparatus

- Offline film thickness measurement apparatus: Optical

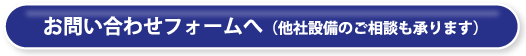

FLOLIA® 3000 Coater System

Testing Unit

FLOLIA® 3000 Coater System

Testing Unit Installation Site

Chugai Ro Sakai Works (Sakai City, Osaka Prefecture)

Unit Specifications

- Maximum substrate size: 1,850 mmW × 1,500 mmL

- Coating thickness: ≥ 1 μm wet (100 nm – 1,000 μm dry)

- Coating viscosity: 0.001 – 100 Pa∙s (1 – 100,000 cps)

- Coating speed: ≤ 200 mm/sec

System Process

- Coater: SLIT COATER

- Reduced pressure drying apparatus: Heat treatment process-capable

- Hot plate

- Film thickness measurement: Coater accessory function

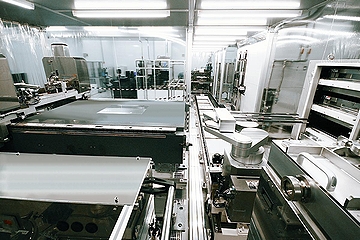

RS Coater

Testing Unit

RS Coater

Testing Unit Installation Site

Chugai Ro Sakai Works (Sakai City, Osaka Prefecture)

Unit Specifications

- Maximum substrate size: 4 – 18 inch (φ450 mm)

- Coating thickness: 50 – 200 μm wet and up

- Coating viscosity: 500 – 15,000 Pa∙s (cps)

System Process

- Coater: SLIT COATER

Clean Oven

Testing Unit

Clean Oven

Testing Unit Installation Site

Chugai Ro Sakai Works (Sakai City, Osaka Prefecture)

Unit Specifications

- Maximum substrate size: G2.5 – G6

- Heating system: Convection type (heated air circulation system)

- Maximum temperature: Max. 550℃

- Furnace interior O2 temperature: ≤ 10 ppm (when using pure N2)

System Process

- Oven

- Film defect inspection apparatus

Contract Testing Requests and Inquiries

- As a rule, there is a charge for testing. (Details of the testing to be performed will be included with the cost estimate provided after application confirmation.)

- If you would like to have testing performed, please click the “Contract Testing Request” button below, fill in the essential fields on the “Testing Request Form” and then submit it.

- Testing requests may be declined, depending upon the content of the request.

- There may be a significant waiting period for testing completion, depending upon the usage status of the testing unit.

* Chugai Ro has testing equipment available for use as part of business discussions with customers interested in systems and equipment purchase and installation. Piecework, once-off testing and other requests are not accepted.