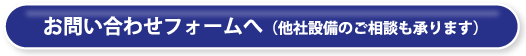

High-precision Coating Equipment

Die Coater for Continuous Lines/RS Coater for Continuous Lines

This fully automated continuous line system performs high-speed, high-precision roll-to-roll coating and drying of paper, films, foils, and membranes. The slot die coating head ensures superior stability and reproducibility in coating quality. The RS Coater head also supports irregular shape coating, intermittent coating, and additional functionality such as lamination and slitting during coating or drying.

The slot die was designed based on fluid analysis and backed by Chugai Ro’s extensive experience.

Our unique highly sealed chamber structure allows for coating even in environments with a low dew point (-70°C or below) and N2 environments!

The equipment doesn’t use a dew point cover, making it easier to handle substrates and significantly reducing the amount of low dew point air or N2 used in environments.

Video of intermittent coating with wheel coater

Video of coating application with wheel coater

(Cleanroom coater example)

■Features/specifications

- Non-contact coating that prevents defects caused by foreign particles or roping

- Closed-loop coating to reduce solution evaporation and prevent changes in coating liquid properties

- Compatible with a wide range of liquids, from low- to high-viscosity (Several mPa·s (cps) to 50,000 mPa·s (cps))

- Compatible with a wide range of coating thicknesses, from thin to thick (Up to 1,000 μm/Wet)

- Compatible with a wide range of coating speeds, from low to high (0.1 to 200 m/min)

- Simple, compact structure for easy maintenance and inspection

- Supports automated control and clean environment processes

- Capable of irregular shape coating, striped coating, simultaneous multilayer coating, and other coating applications

- Coating precision: ±3 to 5% or less

Example of striped coating

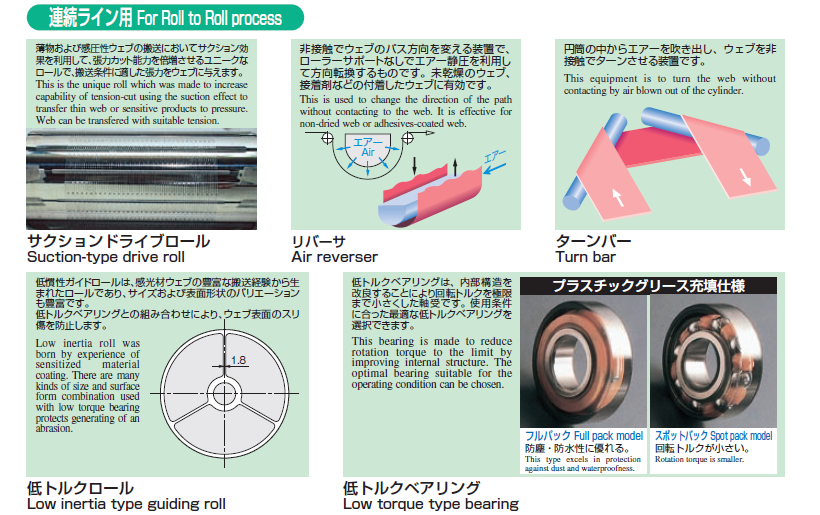

Substrate conveyance technology helps prevent film from becoming scratched or creased during conveyance—an indispensable technology for functional film manufacturing.