Heat Treatment Furnaces for Automobile Machine parts

Vacuum Heat Treating Furnaces

■ Vacuum Heat Treating Furnaces – VF/VFV Series

This furnace is applicable to a wide variety of processes hardening, tempering, precipitation hardening, annealing, solution heat treatment and brazing.

The VF series performs both heating and cooling in one chamber thereby making the furnace compact and also perform gas cooling of max. 1MPa(abs). Furthermore, it also has the unique cooling control function (patent). It requires only small installation space and no dedicated pit. The VFV series is vertical and best suited for heat treating long materials.

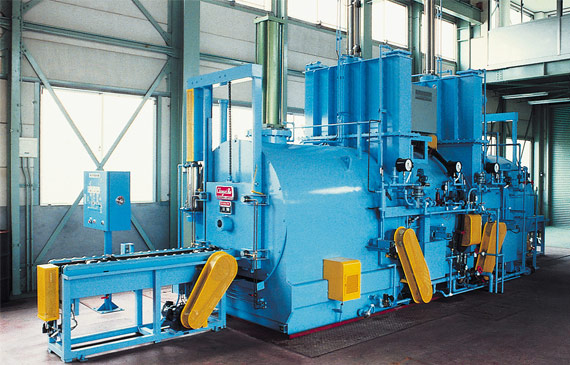

■Vacuum Heat Treating Furnaces – CF/QF Series

This series is used widely for the hardening of tool, alloy and stainless steels, and sintering, brazing and solution heat treatment.

By combining a standard vestibule (gas quench chamber) with a heating chamber and oil quench chamber, a furnace precisely suited to the materials and heat treating purposes can be selected.

This series includes the CF model for gas cooling, the QF mode, in which both gas cooling and oil quenching can be carried out in one chamber, the CF-Q model, in which gas cooling and oil quenching are carried out in separate chambers, the CF-C model, a straight-through type for gas cooling, and the QF-C model, a straight-through type for both gas cooling and oil quenching.

■Vacuum Draw Furnaces – T/VT Series

These low temperature furnaces are designed to operate at temperatures below 750°C. One of the options in this series allows for a maximum furnace temperature of 950°C, and can be used for annealing or normalizing cold forged parts and high-grade wire rods. Another type, the VT series, has an intra-cooler in the furnace, to cool the atmosphere gas directly, which greatly reduces the cooling time.