Heat Treatment Furnaces for Automobile Machine Parts

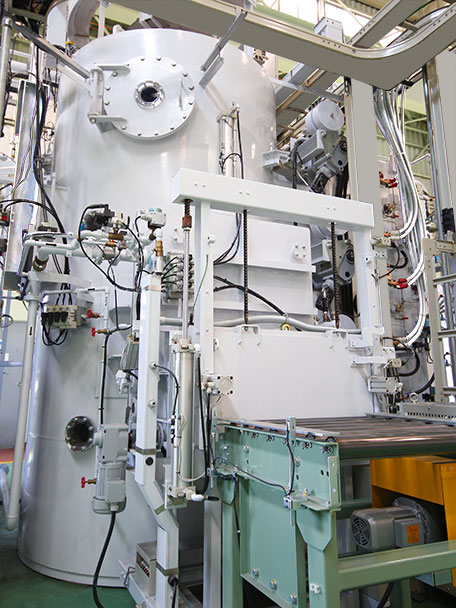

COMPACTFALCON™ Vacuum Carburizing System for Small-lot Production

About Vacuum Carburizing Furnace “FALCON™”

The COMPACTFALCON™ Vacuum Carburizing System for Small-lot Production has a compact design and can be used for in-line processing.

Ancillary equipment for carburizing processing, such as cleaning equipment and a draw furnace, is included in the package with the system, and the whole system can be installed in a compact space of about 50 m2. In-line processing with pre-processing and post-processing machines is also possible.

The system can be customized according to cooling specifications (e.g., gas cooling and oil cooling) for the purpose of material processing.

Reducing the heating time and improving the carburizing accuracy reduces the heat treatment time, and this reduces the amount of coolant gas used for gas cooling, which improves running costs.

Improvement of Product Quality

- A more uniform temperature distribution within the effective dimensions and constant supply of carburizing gas enables heat treatment with less uneven carburization.

- Our original quenching oil rectification mechanism enables uniform velocity distribution, which contributes to reducing distortion.

- The pressure at quenching can be adjusted from vacuum to atmospheric pressure. The most suitable quenching conditions can be set to reduce distortion.

- High-speed transfer at quenching has been achieved, and this contributes to improved quenching performance and further stabilization of heat treatment quality.

Specifications

- Effective dimensions: 600 (W) × 500 (L) × 250 (H) mm

- Max load:100 kg・gross/tray

- Operating temperature: normal 950–1050°C / max 1100°C

- Heat source: electric heating

- Max gas cooling pressure: 1.0 MPa (abs)