Gas Burner

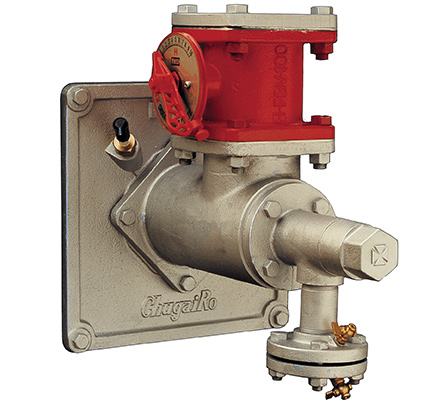

NEOTMG™ throat mix burner

A product series customized for small capacity use has just been added to our lineup of typical models of Chugai Ro’s general gas burners, “Model-TMG Throat Mix Gas Burner.” This series encompasses our next-generation burners equipped with combustion performance higher than conventional similar burners and a safety combustion function (compliant with JIS B 8415-2008) which individually monitors the main and pilot flames. The most optimal size can be chosen from a wide variation according to the firing rate.

Drawing data [zip]→Download

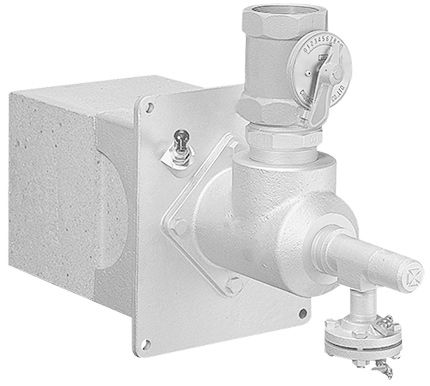

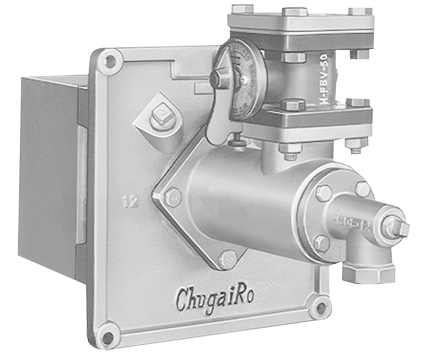

Model TMG throat mix burner

A general-use gas burner with a turn-down ratio of 10:1. Low excess air combustion can be achieved over a full range of firing rates by operating a single valve. No back fire. It is possible to perform direct electric ignition by the use of a spark plug.

Air pressure: 4.5kPa

Hot-TMG throat mix burner for high temperature air

Can use preheated air up to 500℃. With an EBC-i automatic air ratio control system, a stable low excess air combustion is assured despite changes in the firing rate or preheated air temperature.

Air pressure: 4.5kPa

Air temperature: 350℃

Model HMG high-momentum burner

This burner agitates the furnace air effectively by a high-speed flame with a large momentum.

Suitable for uniform and rapid heating. Extremely low generation of free O2 in the reducing combustion makes this burner suitable for oxidation free haeting applications. Can use preheated air up to 500℃.

Air pressure: 5kPa

Air temperature: 20℃

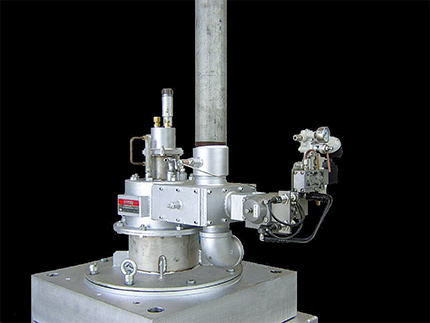

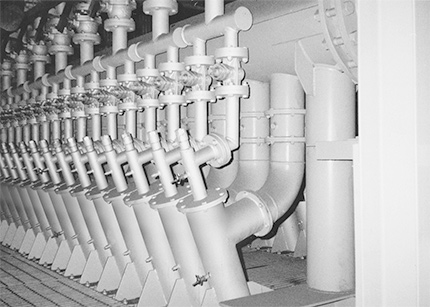

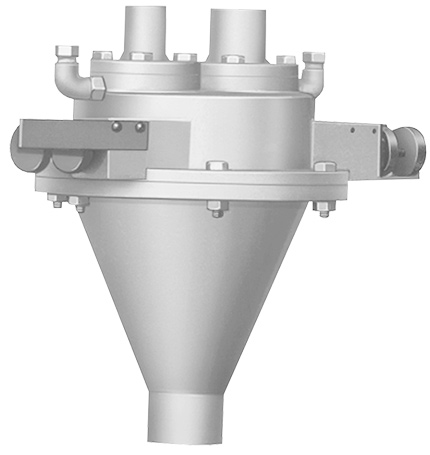

Immersion tube Self Regenerative Gas Burner

A single and compact ISRG unit ensures selectable thermal storage in immersion tube.

The burner has compact body, does not require exhaust gas suction fan(IDF) and is mono-block construction integrating a pilot burner and a valve to select air or exhaust gas. Therefore, the whole system can be downsized with a reduction in cost.

This product is best suited for nonferrous metal melting or holding furnaces with immersion tube where the introduction of conventional regenerative systems is difficult.

The regenerative media uses an alumina ball that is economical and excellent in heat resistance and corrosion resistance.

Model SRMG™ Recu-burner

A fuel-saving high-speed flame burner with a recuperator built in. Can be also controlled with time-proportional ON-OFF control, eliminating the need for complex control devices.

Air pressure: 6kPa

Air temperature: 20℃

Drawing data [zip]→Download

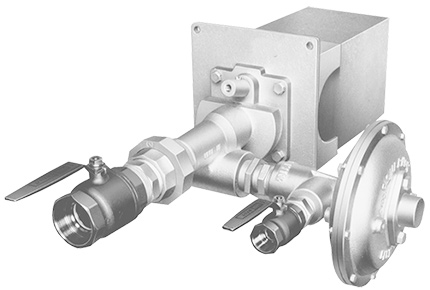

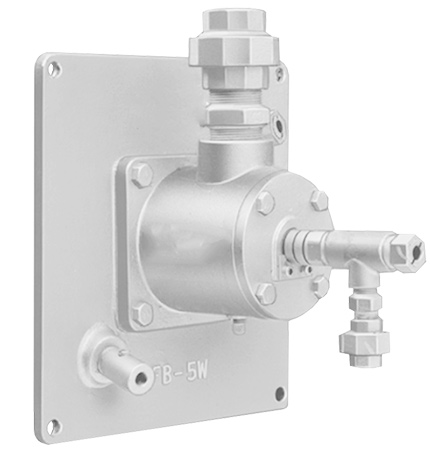

Model VB low pressure velocity buener

This is a premixing burner designed to induce fuel gas proportionately by low pressure air. The firing rate can be proportionately adjusted by controling only the air pressure without changing the air fuel ratio. Suitable for a wide range of application from high-temperature to low-temperature furnaces.

Air pressure: 6kPa

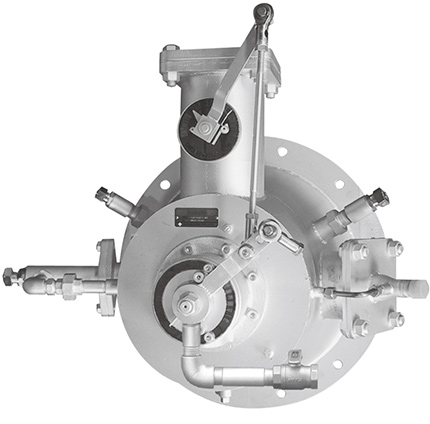

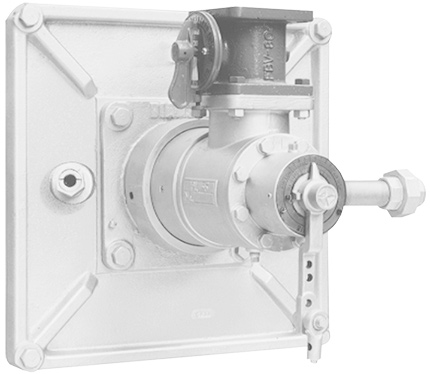

Model DGB double-cone burner

A low-temperature oven burner with a turn-down ratio of 20:1. With a built-in gas and air flow regulator, low excess air combustion can be achieved by the operation of a single lever over a full range of firing rates.

Air pressure: 6kPa

Air temperature: 40℃

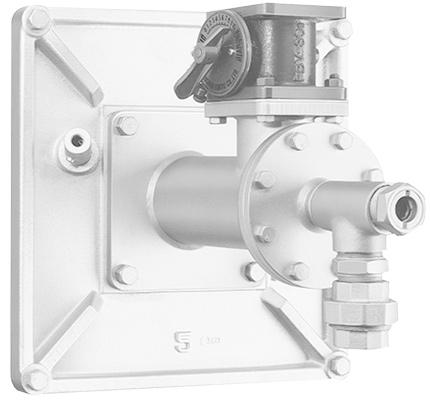

Model HFB™ high-flame burner

A nozzle mix burner that rapidly mixes gas by swirling air at the end of the burner. This model spreads the flame in a radial direction, producing a flat flame. Two models are available; HFB™ for normal temperature air application and H-HFB™ for utilizing preheated air up to 500℃.

Air pressure: 3kPa

Air temperature: 20℃

Model GPL proportional adjustment burner

This is a nozzle mix burner that can achieve proportional adjustment of the amount of gas and air by the operation of a single lever. Since the mounting size and flame characteristics are standardized with those of the PLB oil burner, the combustion chamber can be operated on either gas or oil by changing the burner.

Air pressure: 6kPa

Model NG nozzle mix burner

A general-use burner that allows combustion with fuel gas and air at low pressures. Its simple design and wide turn-down ratio makes this burner suitable for a variety of applications. Model NG-L (firing rate:1740 to 5810kW) is also available for large capacity.

Air pressure: 2.5kPa

Model RFB roof burner

Designed for mounting on the ceiling or sidewall of a reheat furnace, this burner heats the material by the radiation heat from the burner tile, utilizing preheated air up to 700℃.

There are two types available : the standard RFB-I and the RFB-II that allows the alteration of the flame from swirled wide to no- swirled wide or vice versa.

Air pressure: 3kPa

Air temperature: 450℃

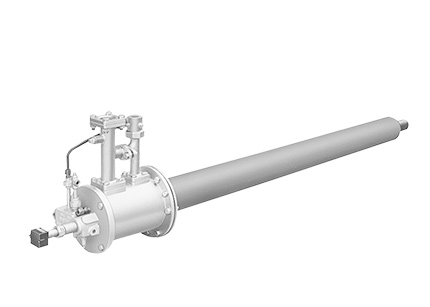

Model CRB concentric radiant tube unit

This is a unitized straight radiant tube heater consisting of a low NOx burner with a built-in recuperator and a radiant tube which uniformly heats the material. It can be used with furnace temperatures up to 950°C. Replacement of the radiant tube with an electron tube is easy.

Air pressure: 4.5kPa

Air temperature: 20°C

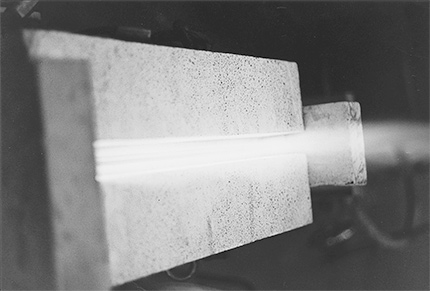

Model CFB-II slit nozzle burner

This burner provides a high speed straightforward horizontal flat flame from a slit-shaped burner tile outlet. Because it has a large flame surface area, this burner has outstanding uniform heating capabilities. It is suitable for direct non-oxidizing heating bacause the free oxygen concentration is very low even when combustion is below the stoichiometric condition. Two models are available model C-CFB-II for ambient air and model H-CFB-II for air preheated up to 500℃ maximum.

Air pressure: C-CFB-II 3kPa (for ambient air)

H-CFB-II 5kPa (for preheated air)

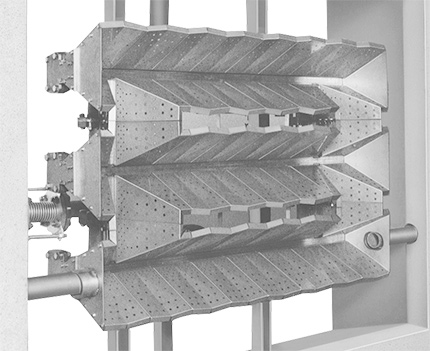

Burner for co-generation system

This system enhances steam generating capacity by heating high temperature, high pressure exhaust gas from gas turbines. This auxiliary heating greatly improves the overall efficiency of a co-generation system. (jointly developed with Osaka Gas Co.,Ltd.)

Firing rate: 2791-25586kW

Fuel pressure: 34.3kPa (at burner inlet)

Turndown ratio: 10:1

Model LS sintering machine ignition furnance burner

This burner contributes to improvement in the quality (strength, ingredient, and grain size) of sintered materials for the blast furnace and also reduces coke consumption. The ignition furnace burner provides uniform ignition by spraying high-speed and high-temperature combustion gas over the entire surface of the raw material. The holding furnace burner can freely adjust the flame length according to the application.

Air pressure: 2.5kPa

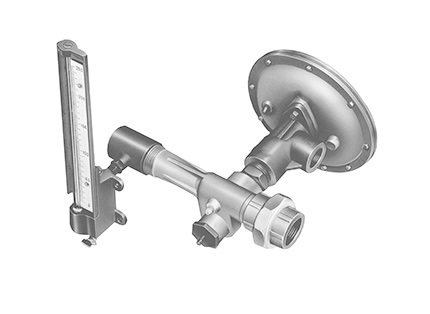

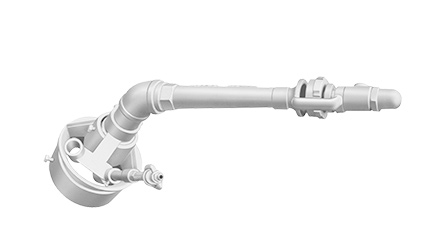

Pilot burner

NPC series and MPN series A nozzle mix type burner on which the flame detector can be installed.

Low pressure inspirator

This is a mixer that induces and mixes fuel gas by using air. Allows proportional adjustment by controlling the air side.

Model M air gas mixer

This mixer is a forced mixing type which allows proportional adjustment by controlling the air intake. Suitable for making a large amount of mixed gas.

Ported tube burner for heating glass

This gas burner is designed for use in local and continuous line heating in combination with perforated heating tubes and features less heat loss caused by exhaust gas.

MODEL WRBG™RADIANT TUBE BURNER

The level of NOx emission has been reduced by exhaust gas circulation and two staged combustion. The use of preheated air is allowed by insert type recuperator. Low excess air combustion produces fuel savings, and the uniform temperature distribution characteristics extend the service life of the radiant tube.