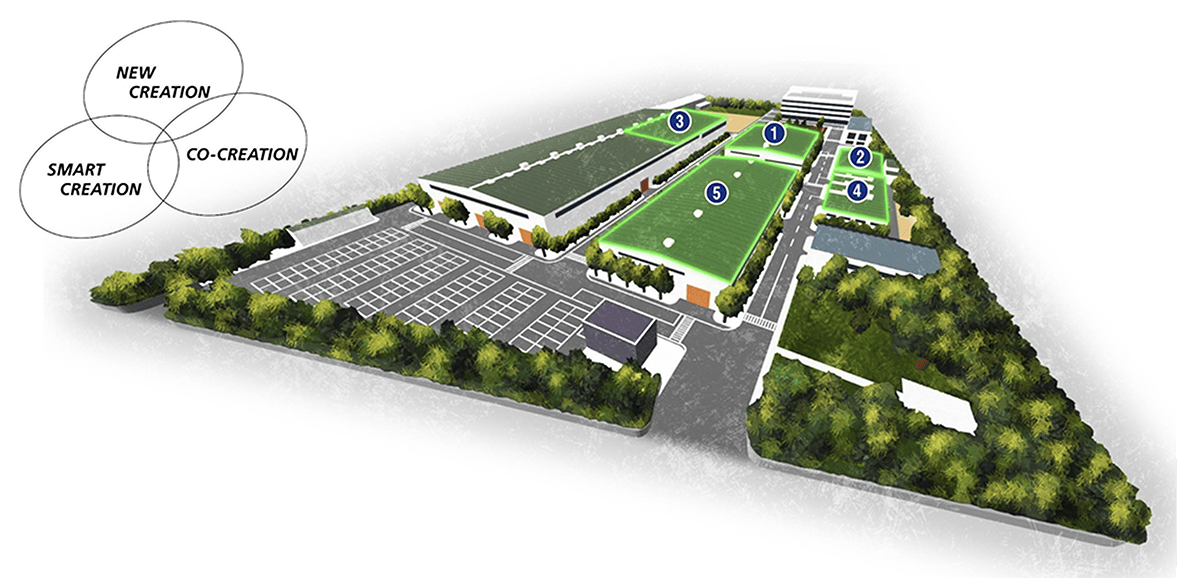

Thermal Technology Creative Laboratory Thermal Technology Creation Center

Evolved into an innovation center by integrating research and development functions.

Thermal Technology Leading the World to a New Dimension

The role of thermal technology is becoming increasingly important, including the development of CO₂ emission-free combustion technology to achieve carbon neutrality, development of heat treatment equipment for EVs, secondary batteries, and semiconductor materials, and innovation of existing thermal technology to meet customers' new product development and production needs. In order to maximize the potential of thermal technology, our core technology, and meet these needs, Chugai Furnace Manufacturing will integrate its various research and development functions into Sakai Works in November 2023. We will accelerate innovation through co-creation with members and partners inside and outside of Japan, and contribute to the creation of a sustainable society.

Thermal Technology Creation Center

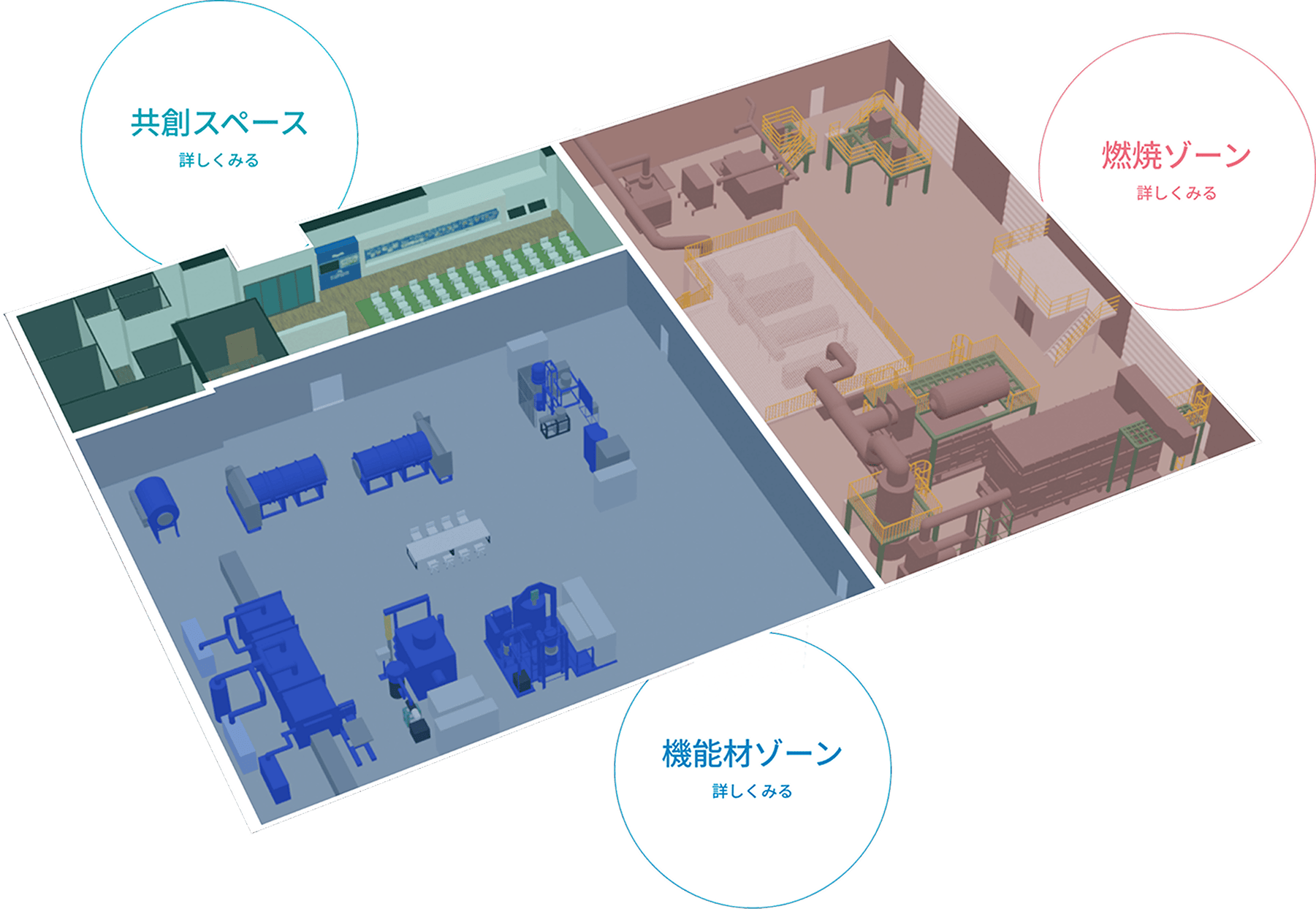

Core facility that plays a central role in innovation creation Thermal Technology Creation Center

Strengthen R&D capabilities and activate internal and external development co-creation,

It is a central facility for our research and development, established to actively and quickly "create new value" as stated in our management philosophy.

Combustion zone

As Japan's leading company in industrial burners, we create a series of decarbonization and energy-saving combustion technology developments.

Demonstration Furnace for Substantial Heating

This furnace allows users to confirm the effects of hydrogen combustion on the substance and to experience the hydrogen combustion flame.

- Furnace Inner Dimensions

- 1,000W x 1,000H x 1,000L

- Maximum combustion volume

- 232 kW

- Supported fuels

- 13A, H₂, O₂

- Maximum furnace temperature

- 1,300°C

1.5MW large scale test furnace

The main purpose of this furnace is to develop large capacity ammonia combustion technology, which will contribute to the realization of decarbonization.

- Furnace Inner Dimensions

- 2,500W x 1,500H x 5,000L

- Maximum combustion volume

- 1.5 MW

- Supported fuels

- 13A, LPG, NH₃, H₂, O₂

- Maximum furnace temperature

- 1,300°C

2.5MW large scale test furnace

The main purpose of this furnace is to develop large capacity burners in excess of 2MW, and tests with multiple burners can also be performed.

- Furnace Inner Dimensions

- 2,000W x 3,000H x 8,000L

- Maximum combustion volume

- 2.5 MW

- Supported fuels

- 13A, LPG, H₂, O₂

- Maximum furnace temperature

- 1,300°C

Medium Test Furnace

The cylindrical horizontal structure allows the furnace length to be divided into four sections, allowing settings to be made according to the purpose of the test.

- Furnace Inner Dimensions

- 800 mm dia. x 4,200 mm L

- Maximum combustion volume

- 0.6 MW

- Supported fuels

- 13A, LPG, H₂, O₂

- Maximum furnace temperature

- 1,300°C

Small test furnace

The main purpose of this furnace is to develop and verify the performance of small capacity burners, and ammonia combustion can also be performed.

- Furnace Inner Dimensions

- φ620 x 2,600L

- Maximum combustion volume

- 0.3 MW

- Supported fuels

- 13A, LPG, NH₃, H₂, O₂

- Maximum furnace temperature

- 1,300°C

Radiant tube furnace

This test furnace is specially designed for radiant tube burners and is capable of testing from 5 to 7 inches.

- Furnace Inner Dimensions

- 600W x 1,250H x 1,600L

- Maximum combustion volume

- 64 kW

- Supported fuels

- 13A, LPG, H₂

- Maximum furnace temperature

- 1,050°C

Simulated tundish furnace

The main purpose of this furnace is to develop energy-saving burners for TD/LD, which can burn downward.

- Furnace Inner Dimensions

- 700W x 1,170H x 4,200L

- Maximum combustion volume

- 1.1 MW

- Supported fuels

- 13A, LPG, H₂, O₂

- Maximum furnace temperature

- 1,300°C

In-flame treatment equipment

This is a multi-functional testing machine for the purpose of developing new processes and demonstration tests of powder heat treatment using a flame.

- Furnace Inner Dimensions

- φ300×3,500H

- Maximum combustion volume

- 174 kW

- Supported fuels

- 13A, LPG, H₂, O₂

- Maximum furnace temperature

- 1,300°C

In-flame treatment mini-tester

This tester is ideal for rapid development of new materials, as it can easily perform small-volume prototyping of in-flame treatment.

- Unit Dimensions

- φ200 x 1,200L

- Maximum combustion volume

- 35 kW

- Supported fuels

- 13A, LPG, H₂, O₂

- Maximum furnace temperature

- 1,300°C

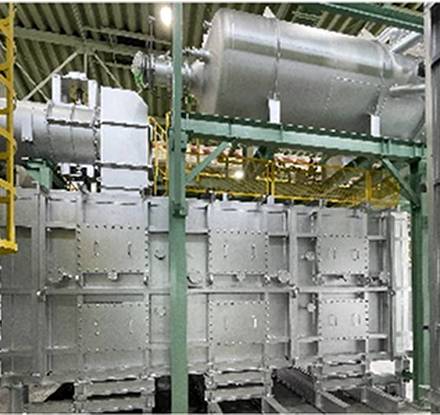

detoxification facility

This equipment removes unburned NH₃ contained in combustion exhaust gas before it is released into the atmosphere. It consists of a detoxifying furnace and a cooling system.

- Dimensions of main unit

- φ1,600×6,000H

- Cooling facilities

- Heat Exchange Type

- Amount of process gas

- 3,000 Nm3/h

- Process gas temperature

- 1,000°C

- Inlet NH₃ concentration

- 10,000ppm

- Outlet NH₃ concentration

- Less than 25ppm

Functional Materials Zone

This zone is dedicated to the development of high-profile materials processing, such as electrolytes for all-solid-state batteries and functional materials for semiconductors.

Furnace for solid electrolyte

Verification furnace for solid electrolyte sintering process. Anaerobic treatment samples can be verified with glove box.

(technical) specification

Furnace temperature: max. 1,000°C, furnace interior dimensions: 440W x 320L x 240H, dew point: DP-60°C

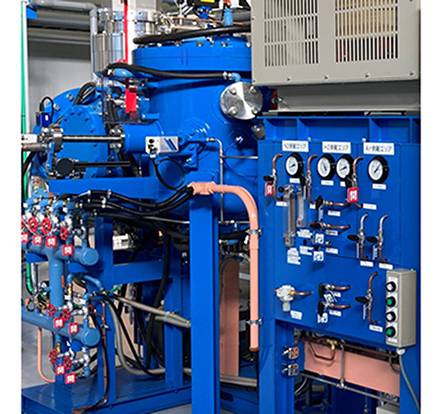

Hot Press

The use of a thick-plate hollowed-out press frame reduces surface curling, deformation, and other age-related changes.

- Furnace Inner Dimensions

- 300 mm dia. x 300 mm H

- Furnace temperature

- 2,500°C max.

- furnace pressure

- Vacuum to 280 kPa abs

- Press pressure

- max.290kN

Decompression CVD furnace (organic materials)

This is a verification furnace for pyrolysis coating process under reduced pressure environment by introducing organic gas.

- Furnace temperature

- 900°C max.

- Furnace Inner Dimensions

- 420W x 420L x 240H

- furnace pressure

- Vacuum to normal pressure

- atmosphere (e.g. musical)

- organic gas

Multi-purpose high-temperature furnace

Suitable for dry purification (halogen-free) and graphitization of ceramics, graphite, etc.

- Furnace temperature

- 2,600°C max.

- Furnace Inner Dimensions

- 150mm dia. x 300mm H

- furnace pressure

- Vacuum to 0.98 MPaG

Three-chamber continuous vacuum furnace

Quality can be checked in a continuous furnace. Contributes to energy saving and running cost reduction.

- Furnace temperature

- max.1,400°C

- Furnace Inner Dimensions

- 600W x 600L x 450H

- furnace pressure

- 1.3Pa abs

muffle furnace

Multi-purpose muffle furnace for degreasing, firing, etc. Ideal for condition setting.

Various sizes are available to accommodate a wide range of temperatures.

- Furnace temperature

- Max. 1,000°C (max. 1,200°C by changing muffle material)

- Furnace Inner Dimensions

- max.φ300×600L

- furnace pressure

- Vacuum to atmospheric pressure

Metal Element Furnace

Contamination-free and hydrogen atmosphere allows for high vacuum to pressurized atmosphere processing.

- Furnace temperature

- 2,600°C max.

- Furnace Inner Dimensions

- 160mm dia. x 200mm H

- furnace pressure

- Vacuum to 0.9 MPaG

- atmosphere (e.g. musical)

- N₂, Ar, H₂

One-chamber gas-cooled vacuum furnace

Rectangular chamber reduces furnace volume and installation space by half compared to conventional models. Gas consumption can be significantly reduced.

- Furnace temperature

- max.1,320°C

- Furnace Inner Dimensions

- 650W x 1,000L x 600H

- Attained pressure

- 7×10-3Pa abs

- Cooling pressure

- 70 to 280 kPa abs

Co-creation Space

A community space that showcases the latest products and our history to promote "showing," "learning," and "gathering" to generate ideas.

Other functional materials testing facilities at Sakai Plant

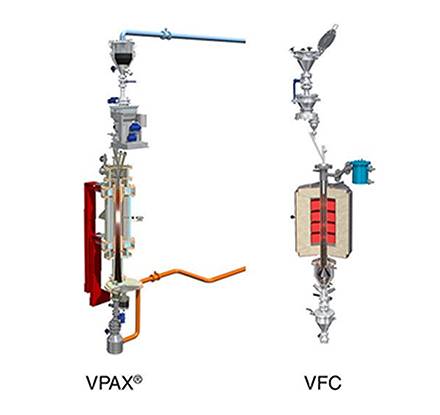

Shaft Type Powder Firing Furnace VPAX™︎ / Vertical Fine Firing Furnace VFC

Vertical furnace for powder materials with container-less conveying. Reduction of energy cost and CO₂ by direct heating can be expected.

- Installation dimensions

- 3,800W x 4,600L x 8,500Hmm

- processing material

- Various powders and powdered materials (5 to 100µm)

- Operating temperature

- Normal use 2,800-3,000°C

- Atmosphere gas

- N₂/Ar

Zero Emission Laboratory

Creating new technologies that contribute to a recycling-oriented society Zero Emission Laboratory

We will further advance the related technologies of Chugai Furnace Industry, which developed sludge treatment and air purification technologies ahead of their time, and develop resource recycling-related technologies, technologies for reducing environmental impact, and technologies for heating and cooling high-performance materials.

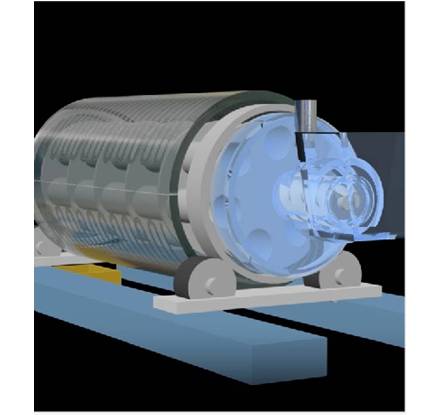

Rotary Kiln

Our unique multi-cylinder structure enables containerless and high productivity.

*The test equipment is a mono-tube type.

No. 1 Tester: For resource circulation and recycling processes

No. 2 Testing machine: For heat treatment process of high-functional materials

- Furnace (retort) dimensions

- 125A x 900L (effective heating length: 600L)

- Heating method

- Electric heating (external heating) method

- Heating Capacity

- max.9kW (3kW x 3 zone control)

- Furnace temperature

- max.1,000°C

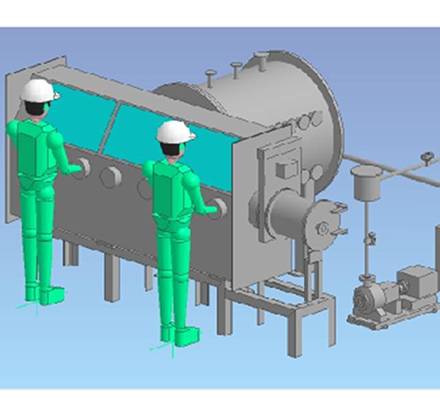

Hydrogen combustion superheated steam heating system

A new decarbonized heat treatment system applicable to degreasing, baking, and recycling processes using superheated steam at ultra-high temperatures with hydrogen combustion.

- Furnace Inner Dimensions

- H400 x W300 x L300 [Processed material size (max.): H150 x W150 x L50].

- Heating method

- Hydrogen x Oxygen combustion method

- Heating Capacity

- max.35kW

- Furnace temperature

- max.1,600°C

- Furnace atmosphere

- Oxidizing atmosphere (O₂=0 to 25%), reducing atmosphere (H₂=0 to 10%)

Vacuum Carburizing Laboratory

Further accelerating the development of our world-class carburizing technology Vacuum Carburizing Laboratory

We will install the latest model of vacuum carburizing furnace, for which needs are expanding, and promote the brushing up of existing technology.

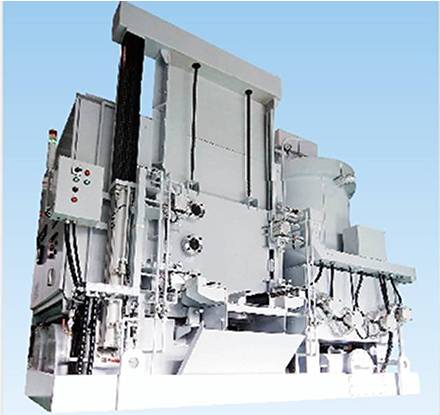

Mass-production vacuum carburizing furnace Hi-Falcon™︎

Processing with this facility, which is layout-free & easy to expand and maintain, can be done in the size of the actual machine.

- Furnace Inner Dimensions

- 760W x 1,220L x 700H

- loading capacity

- Gross 900kg

- Furnace temperature

- 1,100°C max.

Small lot vacuum carburizing equipment, Compact Falcon™︎

This is a carburizing furnace for high-mix low-volume production that is compact and in-line compatible. Equipped with three carburizing chambers, it is capable of processing equivalent to actual facilities. Gas cooling and oil quenching are selectable.

- Furnace Inner Dimensions

- 600W x 500L x 250H

- loading capacity

- Gloss 100kg

- Furnace temperature

- 1,100°C max.

Small lot vacuum carburizing equipment, Compact Falcon™︎(1 carburized chamber + oil quenching)

Special specifications such as nitriding can be accommodated.

- Furnace Inner Dimensions

- 610W x 460L x 220H

- loading capacity

- Gross 70kg

- Furnace temperature

- 1,100°C max.

Metal Heat Treatment Laboratory

Exploring the new value of metals with unlimited possibilities Metal Heat Treatment Laboratory

Equipped with a gas carburizing furnace that can meet all carbon-neutral needs, it opens up new possibilities in metal heat treatment.

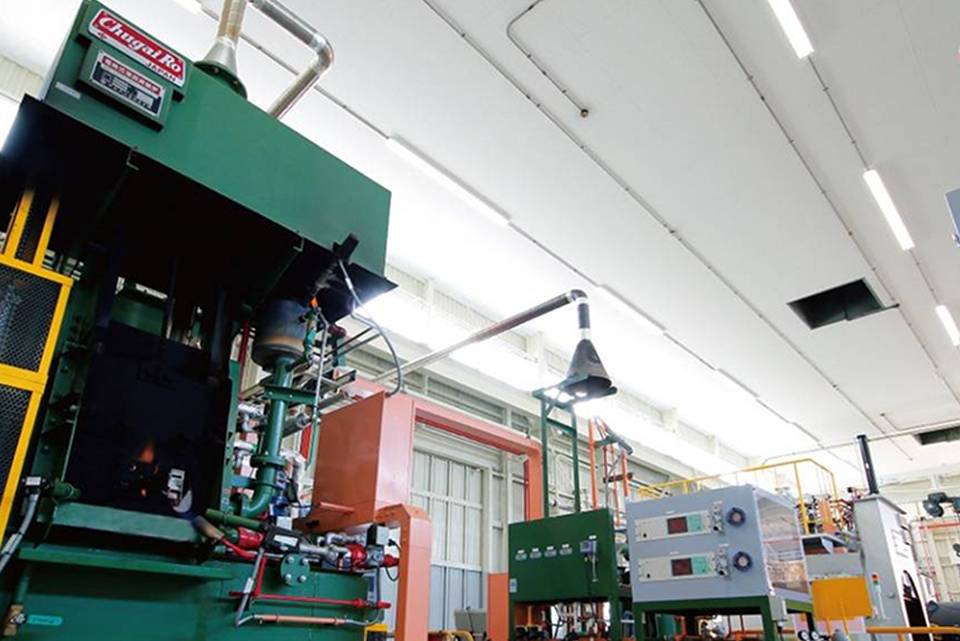

Hydrogen combustion demonstration furnace

Indirectly heated hydrogen combustion burners are installed to achieve carbon neutrality of the heating source.

- Furnace Inner Dimensions

- 610W x 920L x 550H

- loading capacity

- Gross 500kg

- Furnace temperature

- 1,050°C max.

New High Shifter

Shortening time and low distortion processing are possible with an oscillating oil reservoir with a high output heater and servo motor.

- Furnace Inner Dimensions

- 760W x 1,220L x 660H

- loading capacity

- Gross 900kg

- Furnace temperature

- 950°C max.

Batch gas carburizing furnace Hi-Sifter™︎

Best-selling gas carburizing furnace. Ideal for high-mix low-volume production.

- Furnace Inner Dimensions

- 300W x 700L x 300H

- loading capacity

- Gloss 100kg

- Furnace temperature

- 1,050°C max.

Multi-purpose nitriding furnace

Energy-saving type with A-gas generator inside the furnace, which can handle a wide range of temperatures.

- Furnace Inner Dimensions

- 400W x 400L x 390H

- loading capacity

- Gross 70kg

- Furnace temperature

- max.1,000°C

muffle furnace

Multi-purpose muffle furnace for degreasing, firing, etc. Ideal for condition setting.

Various sizes are available to accommodate a wide range of temperatures.

- Furnace Inner Dimensions

- max.φ300×600L

- Furnace temperature

- Max. 1,000°C (max. 1,200°C by changing muffle material)

- furnace pressure

- Vacuum to atmospheric pressure

New vacuum cleaner

Shower & soak for improved cleaning power. Can be tested on actual equipment size in as little as 20 minutes.

- Furnace Inner Dimensions

- 760W x 1,220L x 700H

- loading capacity

- Gross 900kg

- washing-up liquid

- hydrocarbon-based

Convertech Laboratory

Developed one-of-a-kind coating technology Convertech Laboratory

We are expanding the scope of application and lineup of RS Coater™, which is expected to be used in the development and production of the latest semiconductors and batteries.

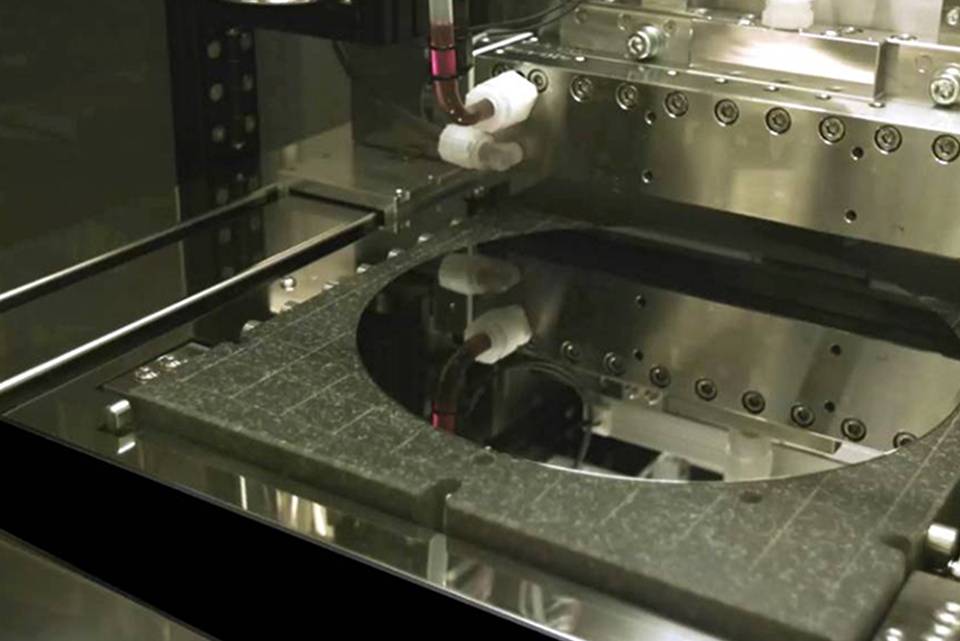

RS Coater™.

This equipment is designed to apply expensive coating liquids evenly and without loss to substrates such as silicon wafers and glass. Coating of irregular shapes is also possible.

- Coating of various semiconductor layers

- IC Package

- MEMS

- Optical adhesive application

- µLED and other FPDs

- Next-generation battery-related materials

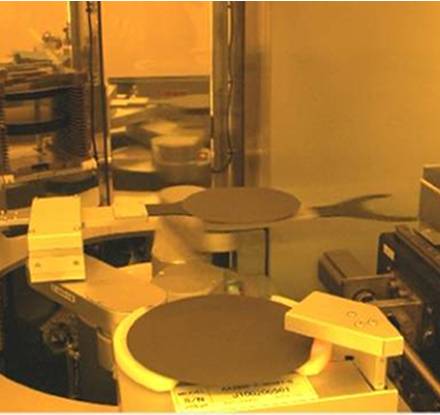

RS Coater™ System

The RS Coater™ is an automated coating and drying system that combines a robot, drying equipment, and baking equipment.

wheel coater

Ideal for coating verification on thin substrates (R2R substrates) such as metal foil and film. Coating of irregularly shaped substrates is also possible.

- all solid-state battery

- fuel cell

- PSC Solar Cells

- OPV

- Semiconductor Processing Materials

Chugai Ro Co., Ltd. prepares test equipment for customers that are thinking of introducing our equipment

You can use the form from the link below for inquiries, applications, etc.

Click here to apply

Access

4, Chikko-shinmachi 2-chome, Nishi-ku, Sakai-shi, Sakai 592-8331, Japan

- By train

- Transfer at Namba Station on the Midosuji Subway Line to the Nankai Train Main Line and get off at Ishizugawa Station. 5 minutes by cab.

- Driving from the north

- Take the Hanshin Expressway Wangan Route and get off at Dejima Exit. 10 minutes.

(Osaka Rinkai Line, turn right at Ishizu Nishimachi intersection) - For those coming by car from the south

- Take the Hanshin Expressway Wangan Route and get off at Ishizu Exit. 5 minutes.