Company History Chugai Ro's History

- 1945 - 1954 Founding of Chuga Ro Co., Ltd.

- 1955 - 1964 Rapid Growth

- 1965 - 1974 Age of Ups and Downs

- 1975 - 1984 The Turbulent 1975-1984

- 1985 - 1994 From Showa to Heisei

- 1995 - 2004 A Big Swell in the Heisei Recession

-

2005 - 2014

The Izanami economy and the BRICs

With economic growth - 2015 - 2024 From Heisei to Reiwa

- 2025 - Creation of new value continues

When World War II ended in August 1945, many Japanese companies went bankrupt due to declining production capacity and inflation. In such a social climate, Chugai Ro Co., Ltd., which was established in April 1945, took steps to strengthen its technical team and made its name known in various industries by publishing technical manuals, etc., and received many orders for forging furnaces, heat treatment furnaces, drying furnaces, etc. In 1950, special procurement demand due to the Korean War helped the company gradually establish a firm foothold in the steel industry. The company's business activities are still going strong today.

In May 1954, we signed a technical cooperation agreement with Surface Conversion, Inc. The introduction of overseas technology supported the development of metal heat treatment technology in Japan.

- Established CHUGAI RO CO., LTD.

- Minoru Tamura appointed as President, and Masao Tanigawa appointed as Managing Director.

- Designated as a special accounting company under the Corporate Restructuring and Improvement Act.

- Published the first issue of "Furnace Guideline," a technical manual.

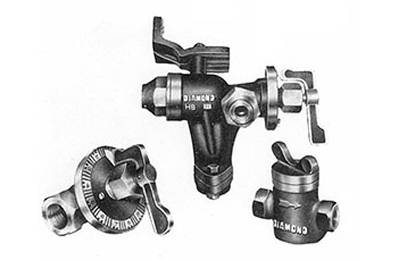

- LB Burner, HB Burner Production

- Osaka Railway Bureau receives order for rail heat-treatment equipment from Kusatsu Materials Depot.

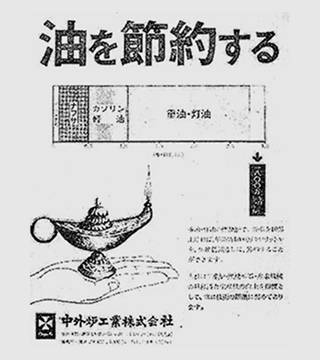

- Published "DIAMOND OIL BURNING APPARTUS," a technical guide to fuel oil

- Receives order for semi-gas forging furnace from the Niigata Railway Bureau's Dozaki Machinery Department.

- Tokyo Branch Office established

- Production of heavy oil burner for ladle

- Received order from Nippon Tire for bicycle body brazing furnace.

- Gas burner production begins.

- Received order for WB type spring burning furnace from the Niigata Railway Bureau's Dozaki Machinery Department.

- Tokyo Office opened

- Manufacture of first hydraulic atomizing burner

- Participated in the Heat Furnace Expert Committee of the Heat Treatment Technology Subcommittee of the Iron and Steel Institute of Japan

- Received order for continuous annealing furnace for cast iron pipe from Kubota Iron Works, Mukogawa

- Received order for the first Walking Hearth Type Steel Plate Heating Furnace from NKK Tsurumi

- Registered three utility models related to burners

- No. 1 export order received for coil annealing furnaces for wire rod to the Philippines

- Received order from Hitachi Zosen Sakurajima for heavy oil-fired cart-type annealing furnace

- Received order from Sumitomo Electric Industries for the first full-scale upper and lower dual-belt continuous billet heating furnace.

- Yawata Office opened

- Long frame burner (LFB) No. 1 machine manufactured

- Orders received exceeded 100 million yen

- Reverse stock split of 25 shares of 20 yen par value into 1 share of 500 yen par value

- Received order for the No.5 equalizing furnace at Yawata Steel's 7-bunk plant.

- Receives order for an annealing furnace from Nippon Malleable Ironworks.

- Increased capital from 200,000 yen to 800,000 yen.

- Received order for aluminum rapid melting furnace from Takada Aluminum Manufacturing Co.

- Increased capital from 800,000 yen to 2 million yen (January)

- Received order for mold core drying furnace from Kameari, Hitachi, Ltd.

- Received order from Kobe Steel, Ltd. and Takasago Corporation for a total of 6 bogie-type annealing furnaces and heating furnaces.

- Juso Plant and Technical Research Institute are newly established.

- Increased capital from 2 million yen to 4.5 million yen (November)

- Delivered the first PLB-type proportional control oil burner to Takada Aluminum Manufacturing Co.

- Signing of Technology Introduction Agreement with Surface Combustion (SC) (May 19)

- Received order for Allcase Reactor Unit 1 and RX Gas Generator from New Mitsubishi Heavy Industries, Kyoto, Japan

- Received order for the first direct-fired bell-type coil annealing furnace from Nippon Teppan and Osaka

The technical tie-up with an overseas company met the needs of the industry at the time, which was eager to introduce the latest facilities and equipment, and the company grew significantly along with Japan, which experienced remarkable growth, increasing its GNP by 3.5 times over the past 10 years.

We also focused on air conditioning, which was not even recognized in Japan at the time, and sold dehumidification equipment. We steadily increased our line of business by entering into technical contracts with overseas companies for secondary processing equipment such as film, paper, and metal coating lines.

It was also around this time that the company began to aggressively expand its business operations, opening the Kokura Plant and the Kashima Plant in Osaka City, as well as a sales office in Nagoya.

- Receives order for wire pattening furnace from Sumitomo Electric Industries, Ltd. and Itami

- Receives order from Kawasaki Seisakusho and Thatchiai for a direct-fired roller hearth type steel sheet annealing furnace.

- Delivered first catenary-type annealing furnace to Nisshin Steel Shunan Co.

- Received order from Asahi Special Glass Funabashi for the first cathode-ray tube lair

- Receives order for Link-Belt Bearing Race Hardening Furnace from Fujisawa in NSK

- Received an order from Kamaishi for the first unit of the upper one-sided furnace in the building in Kamaishi in Fuji Iron & Steel Co., Ltd.

- Received order for the first continuous gas carburizing furnace from Toyota Motor Corp. and Kuremo Co.

- PLB burner patented

- Received order from Yawata for 3-band billet pusher heating furnace from Yawata Steel Co.

- Received order for the first RT type roller hearth bright annealing furnace from Sumitomo Metal Industries, Ltd. and Pipe & Tube Works, Ltd.

- Masao Tanigawa becomes a councilor of the Iron and Steel Institute of Japan.

- Sales exceeded 1 billion yen

- Increased capital to 9 million yen (December)

- Equipment Manufacturing Newly established

- Developed 5-stage pressure booster turbo blower 2HTB

- SC adds "Casabar" to its technology agreement with SC.

- Received order for the first overhead type crankshaft tempering furnace from Sumitomo Metal Industries, Ltd. and Steel Works, Ltd.

- Received order from Usiminas Steelworks, Brazil, for uniform heating furnace and billet heating furnace.

- Masao Tanigawa becomes president of the Japan Industrial Kiln Association.

- Received order for Catenary type strip annealing furnace No.1 from Nippon Stainless and Naoetsu.

- Received order from Konishiroku Photo Industry for the first "Kathabar" machine produced in Japan.

- Completion of the second factory of the Equipment Manufacturing Plant

- Kashima Plant completed

- Received order from Tokai Steel for 5-band billet pusher heating furnace (250 tons/hour)

- Capital alliance with Midland Ross (MR) is formed.

- Masao Tanigawa appointed advisor to the Japan Institute of Metals

- Increased capital from 9 million yen to 36 million yen (July)

- Increased capital to 72 million yen (December)

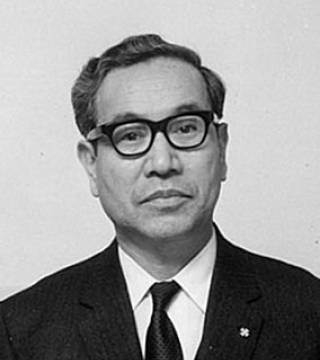

- Masao Tanigawa appointed as President.

- Kokura Plant completed

- Completion of new Hotarugaike Dormitory

- Received order from Konishi Sake Brewery for "Kathabar" for Four Seasons Brewing

- Business alliance agreement signed with Shin Mitsubishi Heavy Industries and Mitsubishi Corporation to promote sales and manufacturing of industrial machinery.

- Increased capital to 288 million yen (October)

- Stock listed on the Second Section of the Osaka Securities Exchange.

- Received order for first tire cord heat treatment system from Otsu Tire Izumiotsu

- Receives order for first photographic paper coating line from Odawara in Konishiroku Photo Industry

- Yawata Office renamed Kitakyushu Office

- Technical alliance with US Steel for automatic alignment roll technology

- Delivered a cover for rustproofing of coils to Tokai Steel Co.

- Received orders for the first continuous coating system for colored steel sheets from Nisshin Steel Ichikawa and Nisshin Steel Amagasaki.

- Increased capital to 302.4 million yen (October)

- Received order from Hitachi Metals, Ltd. Fukagawa for the first atmosphere-type malleable iron continuous annealing furnace.

- Increased capital to 604.8 million yen (April)

- Delivered first gas wiping (YG) equipment to Nisshin Steel, Amagasaki

- Increased capital to 635.05 million yen (October)

Although the first five years of the "Izanagi Boom" saw the Japanese economy continue to boom, the second half saw the "Nixon Shock" and the "First Oil Shock" bring the Japanese economy to a standstill. In the midst of this situation, we not only delivered many of the latest walking-beam heating furnaces to the steel industry, which continued to grow dramatically, and secured an overwhelming share of the market, but also delivered a succession of annealing rare earths, essential for the production of CRT televisions, which were mainstream at the time, to domestic and overseas manufacturers, securing an exclusive market share from 1980 onward. In addition, we delivered a succession of annealing rears, which were indispensable for the production of CRT televisions, the mainstream item at the time, to domestic and overseas manufacturers, leading to our securing an exclusive market share from 1980 onward.

- Receives Order for Equal-heating Furnace from Baotou Steel Works, China

- Delivered first Radiation Burner to NEG Takatsuki

- Masao Tanikawa appointed Vice President of the Japan Industrial Furnace Manufacturers Association

- Signed a business distribution agreement for ultrasonic burners with Todd Shipyard, Inc. of the U.S.

- Delivered continuous galvanizing furnace to Nisshin Steel Co., Ltd. Ichikawa

- Signed an agreement with Shell Research Ltd. of the U.K. to introduce oxygen burner technology.

- Delivered a non-oxidation type thick plate heat treatment furnace to NKK Tsurumi

- Increased capital to 700 million yen (April)

- Delivered the first toroidal burner to Shikama in Japan Iron‐Sand Steel Co., Ltd.

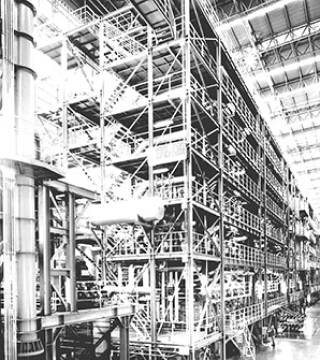

- The first walking beam continuous billet heating furnace is delivered to Fuji Iron & Steel Co., Ltd. Hirohata and Tokai Steel Co.

- Delivered a gas burner for tundish to Mizushima in Kawasaki Steel Co.

- Increased capital to 733,376,000 yen (November)

- Increased capital to 1,164,000 yen (April)

- Delivered the first burner for sinter ignition furnace to Nakayama Steel Works, Funamachi

- Muneyuki Komo becomes chairman of the Oil Burner Research Association

- Increased capital to 1,145.9 million yen (Nov.)

- Sales exceeded 10 billion yen

- Stock listed on the First Section of the Osaka Securities Exchange.

- Signed a contract with Stein Surface (SS) of France to introduce a non-oxidation heating furnace technology.

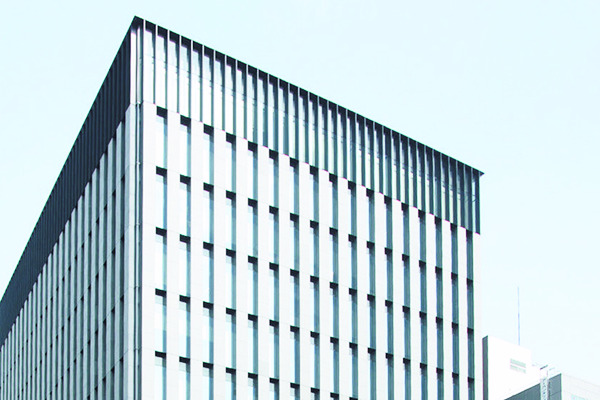

- Head office building completed

- Signed a technology licensing agreement with Stein Atkinson Stordy (SAS) of the U.K. for a WB-type continuous billet furnace.

- Signed a technology licensing agreement with SS for WB-type continuous billet heating furnace.

- Increased capital to 1,494,457,000 yen (November)

- Floater-type aluminum strip annealing furnace delivered to Sumitomo Light Metal Industries, Ltd. in Nagoya, Japan.

- Delivered a toroidal burner for preheating a converter furnace to Sakai in NIPPON STEEL CORPORATION

- Stock listed on the First Section of the Tokyo Stock Exchange.

- Construction of Kashima Plant No. 2 completed; Technical Research Center moved from Juso Plant to Kashima Plant.

- Muneyuki Komo receives an award from the President of the Agency of Industrial Science and Technology for his achievements in thermal management.

- Delivered the first one-chamber vacuum furnace to Toyo Metals Smelting & Refining Co.

- Delivered a non-oxidizing rotary hearth furnace (CSO furnace) to NKK Keihin

- Increased capital to 1,429,527,150 yen (October)

- Delivered a catenary integrated annealing furnace to Shunan, Nisshin Steel Co.

- Increased capital to 1.5 billion yen (November)

- Masao Tanigawa is appointed Chairman of the Japan Industrial Furnace Kosei Nenkin Fund.

- Increased capital to 2.25 billion yen (April)

- Masao Tanigawa is appointed chairman of the Japan Industrial Furnace Manufacturers Association.

- Designed axial-flow-fired WB furnace

- Started development of low NOx burner

- First use of "double insulation method with water-cooled pipes" for WB furnace

- Muneyuki Komo becomes Executive Director of the Japan Thermal Energy Technology Association

- Delivered a uniform heating furnace to Pohang General Steel in Korea

- Delivered color photographic paper coating equipment to the Soviet Union via Konishiroku Photo Industry Co.

- Technical alliance with Hamworthy of the U.K. for burners for marine and power plant boilers

- Manufacture of "high shifter" all-case furnace

- Signed a contract with MSI of the U.S. to introduce a multi-stage furnace technology for sludge incineration.

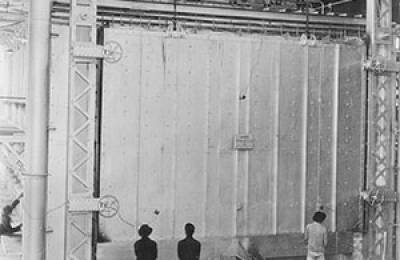

- Large-scale combustion test furnace constructed in Kokura Plant.

- Signed a contract with Zahn Industries, Inc. of the U.S. to introduce sludge thermal processing equipment technology.

- Signed an agreement with Zahn Industries, Inc. to introduce clean room technology.

- Muneyuki Komo is appointed Managing Director of the Japan Thermal Energy Technology Association and Vice President of the Kinki Branch

- Head office building expansion completed

- Receives the Excellent Product Award from the Japan Thermal Energy Technology Association for the high shifter type all-case furnace.

- Delivered a shoe pusher type aluminum slab heating furnace to Mitsubishi Aluminum-Fuji

- Increased capital to 2,418.75 million yen (Nov.)

(Expanded to 8 stories in 1974)

After the second oil crisis in 1979, soaring crude oil prices led to active oil field drilling outside of the OPEC countries, which in turn led to a rush of orders for seamless steel pipes from Japanese steel makers. In response to this capital investment, we delivered a large number of equipment using the latest technology. In addition, we proposed and received orders for the latest type of fluidized bed furnaces in the sewage field, which was expected to grow significantly at that time, especially in the sludge incinerator field where our thermal and combustion technologies could be put to use, and we overcame the severe market conditions.

This decade also marked the beginning of the passing down of the founding spirit to a new generation, as the top management of the company passed from the founder, Masao Tanigawa, to Muneyuki Komo and then to Hiromasa Maekawa.

- WB furnace adopts parent-child door for the first time

- Delivered the first H-PLB type burner to Nippon Insulators

- Sakai Plant completed; Technical Research Laboratory moved from Kashima Plant to Sakai Plant

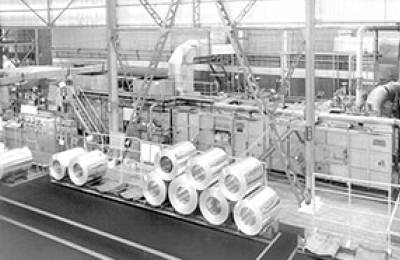

- Cumulative delivery of bell-type strip coil annealing furnaces exceeds 1,000 units.

- Delivered the first multi-stage sludge incinerator to Nishinomiya City, Hyogo Prefecture

- Delivered first clean room unit to Santen Pharmaceutical

- Renewal of Technology Introduction Agreement with Midland Ross (MR)

- Increased capital to 2.66 billion yen (November/Market Issuance Method)

- Signed a technology licensing agreement with Korea Bearing Industries for all-case furnaces, tempering furnaces, and gas generators.

- Increased capital to 2.926 billion yen (April)

- Masao Tanigawa becomes Chairman of the Board and Muneyuki Komo becomes President.

- Increased capital to 3,072.3 million yen (October)

- Kashiwara Research Center established

- Masao Tanigawa passed away on February 20, 1945, and was awarded the Order of the Sacred Treasure, 3rd class.

- Masao Tanigawa Company funeral (March 14)

- H-PLB type burner receives the Excellent Product Award from the Japan Thermal Energy Association.

- Muneyuki Komo appointed advisor to the Japan Institute of Metals

- Muneyuki Komo is appointed Chairman of the Japan Industrial Furnace Employees' Pension Fund.

- Muneyuki Komo is appointed Chairman of the Japan Industrial Furnace Manufacturers Association.

- Developed burn-off furnace

- Approval of extension of the term of the multi-stage furnace technology introduction contract with MSI.

- Muneyuki Komo becomes Managing Director of the Energy Conservation Center, Japan

- Published Masao Tanigawa's memorial volume

- SEA-type high-pressure airflow oil burner receives the Excellent Product Award from the Energy Conservation Center.

- Established Chugai Engineering Co.

- Contract signed for 2 WB heating furnaces for China Steel

- Delivered SR furnace to Hanshin in Kawasaki Steel Co.

- Started sales of TMG type throat-mix gas burner

- Started sales of Mayne Flat Tubes

- Burn-Off Furnace Receives Excellent Product Award from the Energy Conservation Center

- Signed a business agreement with CPSI of the U.S. for HIP (Hot Isostatic Press High Temperature and High Pressure Heat Treatment Equipment).

- Signed a contract with Stein Surface (France) to introduce a rotary drum type charging and extraction system technology.

- Begins sales of FHC-type low NOx burners

- Delivered the first split-bed WB furnace to Kobe Steel, Ltd.

- Completed construction of continuous annealing furnaces (CAL) for cold-rolled steel sheets in the Soviet Union, Japan, and Sweden.

- DGB type burner receives the Excellent Product Award from the Energy Conservation Center.

- UAS furnace delivered to NKK Keihin

- Delivered an aluminum rapid melting furnace to Asahan Aluminium, Indonesia

- Split-bed WB furnace for continuous casting receives the 1st (FY1980) Japan Machinery Manufacturers Association Chairman's Award as an excellent energy-saving device.

- Tanigawa Heat Technology Promotion Fund established

- Technical collaboration with Esher Wyss (EW), Switzerland, on a fluidized bed system for drying and incineration of municipal sewage sludge.

- Delivered a heating furnace for sizing mill in Oita in NIPPON STEEL CORPORATION

- H-TMG type throat-mix gas burner receives the Excellent Product Award from the Energy Conservation Center, Japan.

- Increased capital to 3.6 billion yen (March/Market Issuance Method)

- Received the 2nd (FY 1981) Japan Machinery Federation Chairman's Award for the burn-off furnace as an excellent energy-saving device.

- Concluded a technology licensing agreement (WB type heating furnace) with MR Co.

- Completion of demonstration equipment for EW-type sludge drying and incineration

- Increased capital to 3.96 billion yen (November)

- Taipei office opened

- Signed a technology licensing agreement with Korea General Machinery Co.

- Bright Flame Gas Burner Receives Excellent Product Award from the Energy Conservation Center

- Signed an agreement with Lining Heiskernung, West Germany, to introduce hot cooling system technology.

- New building of Kyushu Branch completed.

- Increased capital to 4.158 billion yen (September)

- Delivered hot-air circulating road heaters to Kashima Road

- Received order from Pohang General Steel of Korea for 2 WB heating furnaces for Gwangyang Works

- Developed CRX (CRG-RC) gas generator

- Delivered the first gas pressure firing furnace for ceramics

- Muneyuki Komo is appointed Chairman and Hiromasa Maekawa is appointed President and Representative Director.

- Signed a technology licensing agreement with Steinhardt & Co. of France for an integrated catenary annealing furnace and WB heating furnace for aluminum billets.

- Signed a technology licensing agreement for UAS with MR Inc. of the U.S.

- Received order from Kyoto Prefecture for sludge granulation drying incinerator

- Muneyuki Komo passed away on December 30.

Despite the arrival of an unprecedented bubble economy in this period, the Company struggled, experiencing operating losses. However, it was able to achieve a significant recovery in business performance due to aggressive public capital investment in the sewerage system, which had been the focus of the Company's efforts for some time. At the same time, the company was promoting fundamental reforms within the company, and in 1991, Tadashi Tanigawa replaced Hiromasa Maekawa as Representative Director, while continuing to work diligently to improve efficiency throughout the company.

Therefore, even as the yen appreciated and the economy plunged into recession after 1990, we continued to grow steadily, thanks in part to the fact that we dared to concentrate on the development of thermal technology without getting deeply involved in real estate or stock investments.

- Muneyuki Komo Company funeral (February 1)

- Hiromasa Maekawa appointed Chairman of the Japan Industrial Furnace Manufacturers Association

- Brilliant Flame Burner receives the "Ota Award" from the Japan Gas Association

- Cross-licensing agreement signed with Somerset Technology, Inc.

- Successive orders for continuous annealing furnaces (CAL) for cold-rolled steel sheets received in Japan, Korea, and Taiwan

- Model RMG Recuburner receives the Excellent Product Award from the Energy Conservation Center.

- Received order from Metalurg for the first CCL for the Soviet Union

- First import of all-case furnace shells from KMC as the first overseas procurement item following the establishment of the Overseas Procurement Section.

- Received order from CHIAP HUA of Hong Kong for a continuous annealing and pickling line (APL) for copper and copper alloys, the first overseas order for an integrated furnace.

- Received order from Aptron for the first exhaust furnace for TV CRT manufacturing equipment for India

- Civisco Corporation is established.

- Announced CNC Plan "Management Vision and Medium-Term Management Plan for the Creation of Chugai Furnace in the New Era"

- Increased capital to 4,324,320,000 yen (Nov.)

- Concluded an agreement with Innotek, Inc. of the U.S. to introduce in-line sputtering equipment technology.

- Received order from China Steel for the first CCL for Taiwan

- Taiwan Chugai Furnace Works, Ltd. established.

- Receives order for the first SBP-type belt press dehydrator from Ataka Kogyo Co.

- Capital participation with the establishment of Harmotech Co., Ltd.

- Received order for 17 units of ultrasonic cleaning equipment from Asahi Breweries, Ltd.

- Received order from CP for first inline sputtering system

- Received order from NGK for continuous hot press.

- Received order from Kyoto Prefecture for the first fluidized bed sludge incinerator

- Established Chugai Tech Co.

- Established Chugai Prox Co.

- Signed a technical and sales assistance agreement with SC for heat treatment furnaces.

- Joint development contract with Idemitsu Kosan for "Ceramic Charcoal Brazier," a heater for consumer use.

- Distributorship and technology introduction agreement signed for Artoor's ultra-high-temperature atmospheric atmosphere furnaces.

- Established Chugai SSG Co.

- Completed first unit of "Reheating Burner" for cogeneration jointly developed with Osaka Gas.

- Received order from Tokyo Metropolitan Government for "Compression Firing Block Conversion Facility"

- Received order from Kyodo Special Steel Wire for the first batch-type wire rod annealing furnace.

- Added technology licensing of heating furnaces, standard vacuum furnaces, and CRG-N gas generators to KMC.

- Participated in the International Garden and Greenery Exposition as a member of the Dairinkai Group

- WB heating furnace orders reach a total of 100 units.

- Received order for "Sludge Incineration Ash Recycling Facility" from Saitama Prefecture via Japan Sewage Works Agency

- HI-SHIFTER annual sales record (43 units) achieved

- Signed joint development agreement with Osaka Gas for intelligent burner system

- Cogeneration use burner for reheating burner receives an award from the 11th Japan Machinery Federation for its excellent energy-saving equipment, together with Osaka Gas.

- Operation CR-MS (proposal system from subcontractors) begins.

- Delivered first blackening furnace to Nisshin Steel Shunan

- HI-SHIFTER annual sales record broken consecutively (44 units)

- Hiromasa Maekawa passed away on October 17.

- Tadashi Tanigawa becomes President and Representative Director

- Hiromasa Maekawa company funeral (November 13)

- High Rock bricks are displayed as "recycled industrial waste" at the Aichi Prefectural Ceramic Museum.

- WB heating furnace delivered to Incheon Steel, Korea, in 13 months, the shortest in history

- WB heating furnace delivered to Hokuetsu Metal (model WB furnace for electric furnaces)

- Received order for the first intelligent burner system unit from Nagano Forge

- Received orders for a total of 700 HI-SHIFTER, and held a technical exchange meeting and a celebration to commemorate the achievement.

- Received order from Gifu City for the first press firing facility in the Chubu region.

- Signed a technology licensing agreement with Beijing Steel Design and Research Institute for WB heating furnace for hot rolling.

- Received order for the first batch-type press firing facility from Osaka Prefecture.

- Received order for the first Solmate machine from IS Seiki

- Signed an agreement with Hotwork (U.K.) to introduce a regenerative burner system technology.

- Chugai Ro Shanghai Office opens.

- Receipt of a turnkey order from ACERINOX S.A. for a continuous stainless steel bright annealing furnace.

- First three-chamber CCF order from Shanghai Natte Fook Conduction Axis for China

- Joint research with the Tokyo Metropolitan Government on liquefied sludge incineration technology is launched.

- Received order from Hitachi Metals and Yasugi for the first soaking furnace for IBS-mounted industrial furnace.

- Received order for the first RTO thermal storage type exhaust gas treatment system from Toyota Motor Corporation Takaoka

- Started joint testing with Osaka Prefecture on sludge deodorization using humus soil

- Received order from Azuma Precoat Ichinoseki for the first CCL with die coater.

- Received order for the first flame treatment system from Sun Aluminum Industries, Ltd. Chiba, Japan

Between the 50th and 60th anniversaries of the company's founding, in-depth management and operational improvements were promoted. These included the establishment of an in-house drafting organization that introduced the latest CAD technology, the integration of the design function with the manufacturing headquarters, the construction of an in-house network, and the aggressive adoption of IT technology such as 3D CAD for the next era.

In addition to management reforms, the company also strongly promoted research and development during this period and struggled to create new products such as high-performance industrial furnaces, thermal storage-type exhaust gas treatment equipment, precision coating equipment for plasma displays and other flat-screen TVs that were expected to become popular, and biomass gasification and power generation equipment. It was a decade that could be described as an era of pioneering new technologies.

- Receipt of orders for thin steel slabs holding furnaces for U.S.A and Korea.

- Won a new large customer in Korea, 2 CCL and 1 CGL orders

- IBS receives award from the 15th Japan Machinery Federation for its excellent energy-saving equipment.

- Received first order from Hitachi Cable, Ltd. Tsuchiura for a roller hearth type annealing furnace with in-pipe purging

- Received order from WK for inorganic powder firing equipment

- TAIWAN CHUGAI RO CO., LTD. relocates its office from Taipei to Kaohsiung City.

- CHUGAI RO OF AMERICA INC. established.

- Added heat treatment furnace-related technology licensed to Hanwha Machinery of Korea

- Signed a technical license agreement with Steinhardt of France for catenary-type stainless steel annealing furnaces.

- Receives order for first Table Coater™︎ for large-size substrates

- Receives order for first SUPLaDUO vacuum deposition system for PDPs

- Signed a technology introduction agreement with Autokumpu (Finland) for rotary support rolls for annealing furnaces.

- Received order for continuous sealing furnace for PDP production

- Received order for the first rotary thermal storage waste gas treatment system

- Completion of Vacuum Evacuation, Encapsulation, and Sealing Test Equipment for Innovating the Final Process of PDPs at the Technical Research Institute

- Established CHUGAI RO (SHANGHAI) CO., LTD.

- Receipt of turnkey orders from Krupp Thyssen Nirosta GmbH, Germany and Taiwanese steel companies for continuous stainless stell bright annealing furnaces.

- Technology transfer to Hanwha Machinery Co., Ltd., Korea on the bubbling fluidized bed type sewage sludge incineration system.

- Developed thermal storage type dioxin decomposition equipment

- Fast circulating fluidized bed incinerator and rotary melting furnace for waste treatment

- ISO9001 certification acquired

- Tadashi Tanigawa appointed Chairman of the Japan Industrial Furnace Manufacturers Association

- Jointly developed with DNP a reflective electron feedback electrode system capable of stably forming PDP protective films.

- Completion of a sewage sludge drying and incinerating system at Kokufu River Basin Sewage Treating Plant in Niigata, Japan which is a new model sewage sludge disposal system for relatively small municipalities.

- Joint development and sales tie-up with Anelva for MgO deposition equipment for next-generation large PDP production

- Received order for the first rotary melting furnace for detoxifying municipal solid waste incineration ash

- Receipt of an order from Acciai Speciali Terni S.p.A., Italy for the world’s largest stainless steel strip bright annealing line.

- Receipt of the first order for a next generation vacuum carburizing furnace.

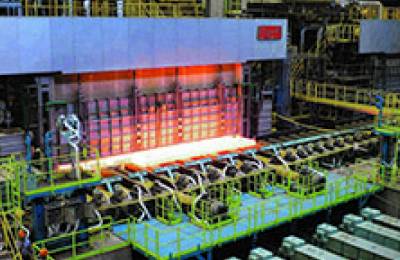

- Installation of an environment-conscious reheat furnace which reduces the fuel consumption to 30% and halves NOx emission as compared with the conventional type.

- Installation of the first order for a dioxin destruction system at Clean Center in Nomura Town, Ehime Pref., Japan.

- Receipt of successive order for TABLE COATER™, MgO deposition system and frit sealing exhausting equipment for mass production of plasma display panels.

- Development and installation of EBC automatic air ratio control device.

- Receipt of order from Avesta Polarit, Finland for the world’s largest annealing furnace for the world’s first full-scale RAP Line.

- Receipt of the first order for a circle drawing coater.

- Receipt of an order for a dioxin destruction system at Oumihachiman City, Shiga Pref., Japan.

- Receipt of an order for one-chamber-type vacuum furnace units 1 and 2 adopting a high-pressurization cooling system.

- Receipt of an order of a bell-type coil-annealing furnace (H2-BAF) for 100% hydrogen atmosphere from Sumitomo Metal Industries in Wakayama.

- Development of the next-generation TABLE COATER™ “FLOLIA™”, which enabled super high-precision paint coating in units of sub microns.

- Receipt of orders of advanced exhaust gas processing systems of bag filter type from Ago-cho, Mie Pref., and the Shirone area in Niigata Pref.

- Installation of steel bar edge heating equipment incorporating an oxygen combustion system in response to an increasing demand for high-quality steel bars.

- Receipt of an order of chicken-dropping carbonization systems as the first equipment making use of organic waste disposal technology from Mori Plant.

- Brisk placement of orders of systems for PDP mass production.

- Development and installation of rotary type regenerative thermal oxidizer, in addition to a one-tower, five-room type, in response to an increasing demand for strong-wind deodorization equipment.

- Receipt of an order of oxygen injection equipment from the Makino Pump Station in the Takashima Valley area in Shiga Pref. for a countermeasure against the generation of hydrogen sulfide in a sewage pipe ditch.

- Receipt of an order of special frit sealing equipment for PDP mass production.

- Installation of the first stripe coater.

- Receipt of an order from North American Stainless, USA, for a stainless annealing line.

- Receipt of the first order from Toyoda Machine Works, Ltd. for a URX™ gas carburizing furnace.

- Receipt of the first order from Jatco Ltd. for a multi incineration system that processes a variety of waste materials simultaneously.

- Receipt of an order from the NEDO (New Energy and Industrial Technology Development Organization) for the Demonstrative Test Project 2002 for Biomass and Other New Energy Sources along with a survey on the project.

- Installation of the first aluminum crucible furnace using a self-regenerative burner and immersion-type burner for an aluminum melting and holding furnace in sequence.

- Simultaneous orders received for three MgO deposition systems for mass production of large PDPs

- Delivered a 110 ton/day circulating fluidized bed incineration system, one of the largest in Japan, to the Rakusai Sewage Treatment Center in Kyoto Prefecture

- Receipt of an order for a full automatic continuous frit sealing and exhaust system for the mass production of large-space PDP facilities.

- Receipt of an order for large-sized drying equipment for industrial waste.

- Receipt of an order for a TABLE COATER™ for large-scale substrates exceeding 2000 mm.

- Receipt of continuous orders from the JICA (Japan International Corporation Agency) for energy-saving promotion equipment for China and Iran.

- Receipt of an order from the Bureau of Port and Harbor Tokyo Metropolitan Government for the removal of an existing incinerator with measures against dioxin taken.

- Delivery of the first flame-type spray synthesizing equipment as a research installation for next-generation rechargeable batteries to Fukui University.

- Release of the FLOLIA 2000 Coater System as an ultrahigh-precision coating and drying system for LCDs and organic ELs.

- Receipt of the order for the large steel plate reheating furnaces for large-scale steels in sequence.

- Receipt of the order for the baking furnaces for developing the FED.

- Receipt of the order for the 150 regenerative thermal oxidizers.

- Receipt of the first order for FLOLIA 2000 Coater System.

In 2005, the engineering staff at the head office, which constituted the majority of the company's workforce, was concentrated at the Sakai Plant, which became the Sakai Office, and the integration of engineering and manufacturing technologies was promoted at a rapid pace. During the difficult decade that followed, new products such as precision coating systems for display manufacturing and photovoltaic cell manufacturing equipment became a major pillar of our earnings, driven by the growth of various industries, and we maintained solid performance even during the global financial crisis that began in 2008.

Although the slowdown of the Chinese economy in 2012 and beyond has once again put us in a difficult situation, we have been able to achieve a recovery in business performance by aggressively proposing capital investment proposals to the strong domestic automobile manufacturers and by completely reviewing our purchasing and procurement costs. In overcoming these difficulties, President & CEO Yoshihiko Sato (2006-) and President & CEO Yuji Nishimoto (2013-) made management decisions with an eye on business conditions.

- Receipt of the order for continuous galvanizing lines for automobile steel strip in sequence.

- Immersion tube self regenerative gas burner (ISRG) won the Japan Machinery Federation (JMF) President Award as 2006 Energy Saving Equipment.

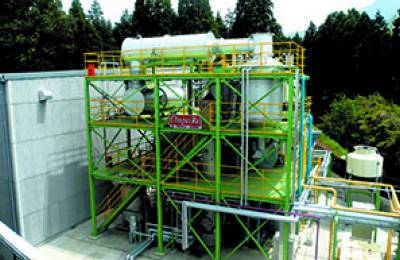

- Achievement of one of the longest 500hrs continuous operation in the world by woody biomass gasification and co-generation demonstrative system at the Yamaguchi Pref.

- Receipt of the order from domestic and overseas steel mills for reheating furnaces and metal processing lines in sequence.

- Biomass gasification and co-generation technology won the Global 100 Eco-Tech Awards from Nihon Keizai Shimbun, Inc. and Japan Association for the 2005 World Exposition.

- Construction is completed on the Sakai Works Engineering Center.

- Biomass gasification and co-generation system won the Japan Organics Recycling Association (JORA) President Award.

- Brisk placement of orders of regenerative thermal oxidizers for amendment of Air Pollution Control Law.

- Tadashi Tanigawa appointed as Chairman of the Board, and Yoshihiko Sato appointed as President.

- Receipt of the orders for the optical film production lines in sequence.

- Receipt of the orders for a motor core annealing furnace and a continuous gas carburizing furnace by local content in sequence, in response to an increasing demand for the motor and the electrical appliance in China.

- Receipt of an order from a liquid crystal display (LCD) maker in China for a FLOLIA 2000 coater system as a mass production line of the large size substrate.

- Receipt of an order for a degreasing furnace for a new development of motor exhaust gas purification equipment.

- Receipt of the first order for a new model regenerative thermal oxidizer.

- Receipt of an order for a source gas heating system for the production of the silicone.

- Receipt of an order for a biomass gasification and co-generation system in Aso City, Kumamoto Pref., Japan.

- Receipt of an order from Shanghai STAL Precision Stainless Steel Co., Ltd.(STAL), China for a continuous ultra-thin stainless steel strip bright annealing line (SUS-BAL).

- Receipt of an order for a biomass gasification and co-generation system in Iwakuni City, Yamaguchi Pref., Japan.

- Receipt of an order for an intermittent continuous coater as an expand to the fuel cell market.

- Receipt of an order for a vertical loading type clean baking furnace for the mass production test of the flat panel display (FPD).

- Receipt of an order for a vacuum deposition system SUPLaDUO for the production of the organic light emitting diode (OLED) display.

- Receipt of an order for an in-flame treatment equipment.

- Installation of a new model recu-burner for heat treatment furnace at PSM, Inc., Korea.

- Receipt of an order for a large size TABLE COATER™ for ITO (transparent conductive films of indium tin oxide) coating

- Receipt of the orders for equipment for space and aviation industries

- Receipt of an order for special heat treatment furnace of magnetic materials

- Receipt of an order for Japan’s first gas quench type continuous gas carburizing furnace, which is environmentally friendly and contributes to reduction in the amount of distortion in heat treatment.

- Completion of a pilot plant for compact type biomass gasification and co-generation system at Sakai Works

- Have received a total of 250 orders for the regenerative thermal oxidizer (RTO)

- Receipt of an order for vacuum clean dryer for the glass substrate for flat panel display

- With strong demand throughout the world continuing for steel products, have received orders from steel mills in Japan, Korea, and Taiwan for environmentally friendly reheating furnaces able to substantially reduce energy consumption.

- Completed the demonstration of new FLOLIA 3000 coater system able to handle G6 (1850 x 1500 mm) substrates.

- Nagoya Sales Office moved to the Honshu- Meieki Building.

- Acquired a total of 3 million of our own shares in three lots on August 24 and December 21, 2007, and February 28, 2008.

- Receipt of an order for the FLOLIA 3000 coater system for electronic paper manufacture.

- Receipt of the orders for equipments for productions of secondary batteries, fuel cells, and solar batteries.

- Total orders received for TABLE COATER™ series broke through the 150 mark.

- ISO 14001 certified.

- Continuing receipt of orders for carbon heat treatment furnaces due to increase in demand for carbon products.

- Receipt of an order for a TABLE COATER™ for the world’s biggest ever substrates (over 4,000mm).

- Ongoing receipt of orders from chemical companies, tire makers, and others, for large-scale regenerative thermal oxidizers (RTO).

- As part of the worldwide trend to prevent global warming, the use of regenerative burners is making progress in the cast and forged steel industry.

- Ongoing receipt of orders from steel mills in China and Korea for continuous annealing lines in response to growing demand for stainless steel strip.

- Have acquired a total of 5 million of our own shares through the acquisition of 1 million on December 22, 2008.

- Receipt of the first order for the regenerative-burner-compatible Easy & Eco. Burner Control System.

- Have received a total of 300 orders for the regenerative thermal oxidizer (RTO)

- Renewal of the demonstration equipment for continuous vacuum deposition of rolled film to satisfy the demand for flexible displays and touch-screen panels.

- Regenerative burner further developed for use with steelmaking process such as ladle preheaters.

- Completion of Kokura Factory refurbishment.

- Installation of the No. 1 Exhaust Gas Condenser in order to utilize waste heat of 180˚C and over, amidst increasing demands for plant energy savings and CO₂ emission reductions.

- Installation of a small scale biomass gasification system in Takayama, Gifu Prefecture.

- 5.6 million shares retired.

- Announcement of agreement with Solar Frontier (formerly Showa Shell Solar) upon the introduction of CIS solar batteries into Solar Frontier’s mass production plants as a result of joint technical development with Showa Shell Sekiyu K.K. and Solar Frontier.

- Ongoing receipt of orders for coater systems for next generation displays (touch panels, electronic paper, 3D displays, etc.)

- Total number of Easy & Eco. Burner Control Device (EBC series) supplied tops 500.

- Renewal of continuous die coating demonstration equipment following that for continuous vacuum deposition of rolled film.

- Total orders received for TABLE COATER™ series broke through the 200 mark.

- Ongoing receipt of orders domestically and from Taiwan and China for large-scale regenerative thermal oxidizers (RTO).

- Ongoing receipt of orders from China and Vietnam for large-scale world-class steel strip processing lines.

- Business of sewerage to government offices transferred to MetaWater Service Co., Ltd.

- Acquired 1 million own shares.

- Installation of Solar Frontier 50kW CIS solar battery panels in the Kokura Factory reducing CO2 by approx. 21 tons per year.

- Ongoing receipt of orders for large-scale internal renovation work on walking beam type reheating furnaces.

- First order for frit baking furnace for organic EL displays.

- Acquired 1 million own shares.

- Developed rechargeable battery electrode material baking furnace “VPAX™” and introduced it in the exhibition concerned.

- Receipt of orders for ceramic powder baking equipments using flame-type powder heat treatment technology.

- ¥30 million and emergency goods donation for reconstruction and victim relief following the Eastern Japan Earthquake.

- Achieved a new record for TABLE COATER™ orders because of vigorous Taiwan/China demand for touch screen coater.

- Transfer of consolidated subsidiary “Chugai Air System Co., Ltd.” shares to T-NET JAPAN Co., Ltd.

- Orders for large-scale steel strip coating lines received from Taiwan, as from Vietnam in 2010.

- Receipt of an order for a vacuum deposition system SUPLaDUO for the production of the organic light emitting diode (OLED) display.

- Acquired 1 million own shares.

- Awarded the 2011 Magnolia Award by the City of Shanghai (received by Toshikatsu Koto, Plant Division).

- Surge in orders received from China for heat treatment furnaces for electrical appliance and auto parts.

- Large ongoing orders for burners for cold-rolling equipment in India and hot-rolling equipment in Thailand.

- Receipt of orders for glass baking furnaces for electronic parts.

- Receipt of order of glass annealer for production of touch panels.

- Orders for FLOLIA™ for flexible organic EL displays.

- Order for a coater system for organic EL illumination.

- Installation of test equipment for a laminating system for large-scale displays.

- Order from Taiwan for FLOLIA™ for touch panels.

- Awarded the Japan Institute of Energy (JIE) Progress Award (Engineering) for technology for biomass gasification and co-generation power systems.

- Receipt from Indonesia of order for continuous gas carburizing furnaces following that for batch-type heat treating equipments.

- Acquired 2 million own shares.

- Receipt from Taiwan of order for aluminum strip coating line.

- Established local corporations (subsidiaries) in Thailand and Indonesia.

- Established a business continuity plan (BCP).

- Order from Minamisannriku-cho, Miyagi Prefecture, for biomass gasification and co-generation system to process disaster rubble.

- Numerous orders for ultra-low NOx burners.

- Ongoing receipt of orders for heat treatment equipments from Mexico, Vietnam, Thailand and Indonesia spurred by increasing overseas production by auto manufacturers.

- First order for induction heater for non-magnetic body.

- Order for roll-to-roll coating line for high-performance film.

- First order for medical-related coater.

- Acquired 2 million own shares.

- Development and launch of consecutive models of new-type energy saving burners.

- Yuji Nishimoto appointed as President.

- Domestic and overseas orders for automotive parts heat treatment equipment.

- First order for the new model self-regenerative burner.

- Supply of a biomass gasification and co-generation system with the bio-coke production system of Yokote City, Akita Pref., Japan.

- Installation of a working demonstration equipment at a bio-coke production system.

- Order for development equipment for organic EL illumination.

- First order for a new model bio-coke production system.

- Acquired 2 million own shares.

- Total orders for regenerative burners top the 2,000 pair mark.

- Demonstration run of bio-coke technology in Kawamata-machi, Fukushima prefecture, to reduce amount of decontaminated waste.

- Orders from China for use in heat treatment of organic EL displays and new-model high precision coating equipment (HP coater).

- Orders from China Steel Corporation for two energy-saving type (for slab hot-rolling) reheating furnaces.

- Order for newly developed OCR coater for lamination of liquid crystal and touch panels.

- Order from Kobe Steel, Ltd. for energy saving-type heating furnace.

- Order from Fuji Heavy Industries Ltd. for newly developed (multiple chamber cell-type) vacuum carburizing furnace HIFALCON™.

- Carries out a Decontamination Technology Verification Project for the Ministry of the Environment at Kawamata-machi, Fukushima Pref., as an experiment for verification, using bio-coke technology.

Riding on the tailwind of the ongoing Abenomics, we reorganized our organization, searched for and developed next-generation products and technologies in order to strengthen our management structure.

In 2020, however, a new type of coronavirus caused a worldwide pandemic. In the same year, Akira Ozaki, who replaced Yuji Nishimoto as President and Representative Director, promoted the transformation of the company into a structure that can always respond to changes in the business environment, while further instilling the management philosophy into the company. In addition, the company reorganized its R&D facilities for the first time in 37 years, including the establishment of the "Thermal Technology Creation Center" in 2023. The Company's business performance is on an upward trend once again, and it will be moving to the Tokyo Stock Exchange's prime market, which was established in 2022.

- Order for polyimide (PI) coater and clean oven in China.

- Order for a bark-burning biomass boiler, as a local revitalization project in Tono City, Iwate Pref.

- Order from Japan for large-size heat treatment equipment for glass.

- Order for roll-to-roll coating line and glass baking furnace for electronic component.

- Total number of Easy & Eco. Burner Control Device (EBC series) supplied tops 1000.

- Order for a continuous stainless steel strip bright annealing line (SUS-BAL) in China.

- Order for heat treatment equipments for wind power generator parts.

- Order from Southeast Asia for aluminum strip coating line.

- Orders from China and Taiwan for coater systems for production of displays.

- Established local corporations (subsidiaries) in Mexico.

- Order from Thailand for continuous galvanizing line (CGL).

- Domestic and overseas orders for coater systems for production of flexible organic EL displays.

- Order from Bamboo Energy Co., Ltd. for Biomass Boiler and Organic Rankine Cycle System for Co-generation.

- Ongoing receipt of orders for coaters of solar battery panel production from overseas makers.

- First order for a new model HI-SHIFTER™ and a new model vacuum cleaning system.

- Domestic and overseas orders for HI-SHIFTER™.

- Domestic and overseas orders for continuous gas carburizing furnaces.

- Order form domestic maker for HIFALCON™.

- Domestic orders for continuous copper strip bright annealing lines.

- Completed the demonstration of FLOLIA™ coater system is available from substrate cleaning to inspection of coated layer.

- Order form Iwatani Corporation for biomass air-heating furnace for Showa Chemical Industry Co., Ltd.

- Conclusion of a contract execution of solo partnership and license agreement with KOHLBACH Holding GmbH, Austria for selling biomass boiler in Japan.

- Ongoing receipt of orders for equipments for development of next-generation batteries.

- Domestic orders for FLOLIA™ coater system for PI (polyimide) coating.

- Aluminum melting furnace dedicated regenerative burner awarded the 2018 Development Prize by the Japan Aluminum Association.

- Domestic and overseas orders for various carburizing furnaces for automotive parts, such as the new HI-SHIFTER™ model.

- Domestic order for continuous copper strip bright annealing line.

- Domestic order for clean oven for mass production of organic EL products.

- Domestic order for energy-saving reheating furnace.

- Development of world’s first general-purpose hydrogen burner for industrial use by Toyota Motor Corporation in collaboration with Chugai Ro.

- Domestic order for large-scale modification project of reheating furnace for steel and new installation of reheating furnace for special steel.

- Large number of orders for functional material and carbon heat treatment furnaces for semiconductors.

- Order for a continuous stainless steel strip bright annealing line (SUS-BAL) in China.

- Order from China for a high precision coating system for organic EL displays.

- Orders for newly installation and modification of coater systems/lines for high-functional film in several countries.

- Order for a regenerative thermal oxidizer (RTO) for a still mill.

- Order for FLOLIA™ coater system for PI (polyimide) coating in China.

- Yuji Nishimoto appointed as Chairman of the Board, and Akira Ozaki appointed as President.

- Development of fossil fuel-free combustion technology powered solely by ammonia (joint research with Osaka University).

- Market release of RS Coater™ as new wafer coating equipment.

- Orders steadily arriving for large-scale oxygen burner used in restarting domestic blast furnaces and in other applications.

- Orders arriving for the Chinese market-targeted, world’s largest continuous stainless steel strip bright annealing line.

- Stronger support for solid-state battery electrolyte manufacturing equipment mass production.

- Orders arriving for fuel cell electrode catalyst material mass production equipment.

- Order for high-precision PI(polyimide) coating system for mass-production model flexible organic EL substrates in China.

- Order from customer in China for high-precision coating system for IC packaging.

- Market release of the CRism™ IoT package for heat treatment equipment.

- Order, continuing from last year, for the world’s largest continuous stainless steel strip bright annealing line in China.

- Launch of the Decarbonization Project to accelerate the development of decarbonization technology, including ammonia and hydrogen burners.

- Conclusion of a contract for the Research, Development and Demonstration of Technologies for Ammonia Co-Firing Thermal Power Generation program of the New Energy and Industrial Technology Development Organization (NEDO).

- Receipt of a domestic order for the first RS coater™.

- Order from Subaru Corporation for a small-lot processing type vacuum carburizing furnace.

- Receipt of a domestic order for a small hydrogen burner test furnace.

- Domestic order for energy-saving reheating furnace to be used for wind power generator-related materials.

- Ongoing receipt of orders for steelmaking combustion equipment which contributes to low-carbonization (energy-saving) efforts in Japan.

- First order for electric furnace dust zinc recycling equipment to be used in the resource recycling process.

- Moved from the Tokyo Stock Exchange 1st Section to Prime Market following market restructuring.(April 4, 2022)

- Receipt of an order for the radiant tube hydrogen burner No. 1, which contributes to decarbonization.

- Ongoing receipt of orders for overseas projects involving high-grade steel strip manufacturing equipment.

- Receipt of an order for Japan’s first hydrogen combustion exhaust gas treatment equipment which contributes to decarbonization.

- Order for a hydrogen combustion test furnace which contributes to carbon neutrality at a plant of customer in Japan.

- Awarded the Cogeneration Award 2022 “Excellence Award” in the Technological Development Category for “commercialization of a waste-heat boiler equipped with a 30% hydrogen co-combustion reheating burner.”

- Order from Denso Corporation for a hydrogen combustion-type afterburner furnace for Denso Fukushima Corporation.

- Joint development with Olympia Kogyo Co., Ltd. of a gun-type hydrogen burner.

- Official signing of decarbonized ultra-thin precision stainless steel bright annealing line with YIEH UNITED STEEL CORP. (YUSCO) of Taiwan.

- Closed and sold Combustion Research Laboratory (Kashiwabara City, Osaka Prefecture) due to transfer of functions to Sakai Plant.

- Integrated and reorganized research facilities within Sakai Plant and opened the Thermal Technology Creative Laboratory.

- Orders for vacuum furnaces are strong due to the trend toward electrification in line with the promotion of decarbonization.

- Receipt of the batch type carburizing furnace line for EV parts for the U.S.

- Favorable orders for decarbonized combustion equipment such as heat treatment furnaces for semiconductor and battery-related functional materials and hydrogen burners.

- Received order for roll-to-roll coating equipment for all solid-state batteries for the Japanese market.

- Orders for heat treatment furnaces for battery materials and maintenance business for heat treatment furnaces remained strong.

- Orders for In-flame treatment equipment, Large combustion equipment, and Hydrogen burner, Ammonia burner, and Energy-saving burner remained strong.

- September 2024 Signed a strategic alliance with Microwave Chemical Co., Ltd. for the design and manufacture of microwave rotary hearth furnaces for ore refining.

- Received a series of orders for RS Coater™ series precision coating equipment for rechargeable batteries and semiconductors in Japan.

As the world's situation changes more rapidly than people can imagine, Chugai Furnace Manufacturing has continued to evolve in order to deliver products that meet the needs of our customers. This belief has been passed down from generation to generation based on our management philosophy of "creating new value through thermal technology. In this new decade, we will continue to create new values that steadily meet the needs of the times, aiming for a prosperous society where people and the earth coexist in harmony, based on the wealth of experience and achievements we have accumulated over the years to become a 100-year company.

- Development of hydrogen-fired regenerative burner that achieves significant energy savings

- A series of decarbonization technologies including a hydrogen-fired afterburner furnace that we delivered to Denso Fukushima Corporation received the "Toyota Technology Development Grand Prize" (jointly awarded with Denso Corporation).

- Received an order from a European customer for a major energy-saving modification of existing plant facilities to achieve carbon neutrality

- Delivered Japan's first commercial-scale ammonia burner for a cement temporary combustion furnace of UBE Mitsubishi Cement Co.

- Orders received for next-generation battery manufacturing facilities, solid electrolyte sintering facilities, and titanium manufacturing facilities for the domestic market

- Recognized as one of the 2025 Excellent Corporations for Health Management (Large Corporation Category)

- Received an order from Kobe Steel, Ltd. for "Modification of Hot Dip Galvanizing Steel Sheet Facility"

- Received an order from Tokyo Steel Corporation for "hot dip galvanizing line modification" (via Ply Metal Technologies Japan Co., Ltd.) and the first commercial unit of an electric furnace dust recycling facility.

- Received orders for small lot vacuum carburizing equipment "COMPACTFALCON™" from Toyota Motor Hokkaido Co.

- "COMPACTFALCON™" received "Technology Development Award" from Toyota Motor Hokkaido Co.

- Strong orders for energy-saving combustion equipment as steel mills shift to electric furnaces to decarbonize their operations

- MOU concluded with China Steel Corporation (Taiwan) on decarbonization combustion technology