Research and Development R & D

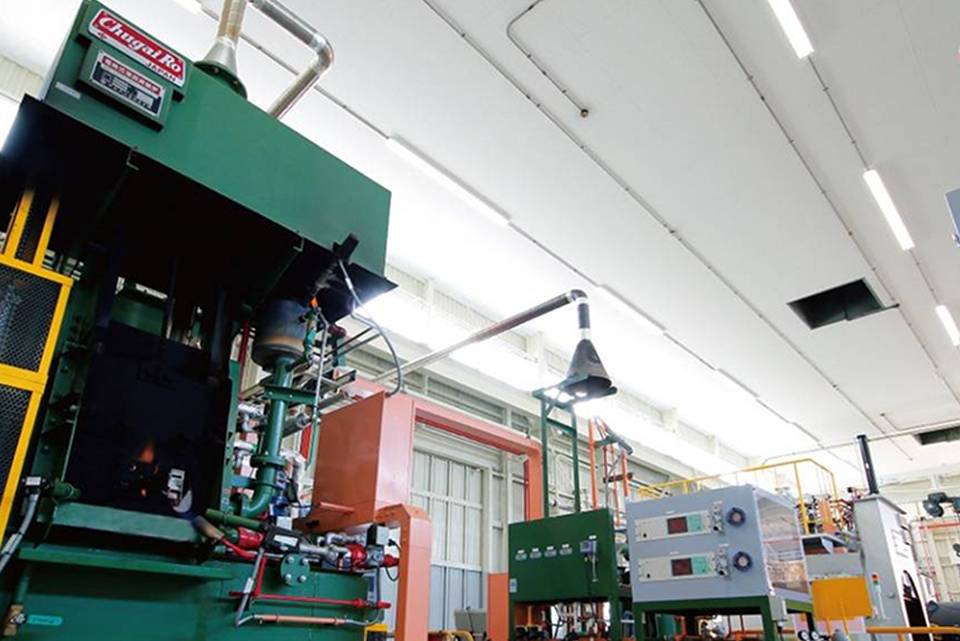

Research and Development ChugaiRo's Technology

Chugai Ro's Three Strengths

Employees who create new value

CHUGAI RO CO., LTD. has developed over the years.

Heat treatment technology, design technology, and state-of-the-art technology.

Based on the three fundamental technologies, we are developing energy-saving and

We have been providing products adapted to social needs such as environmental protection.

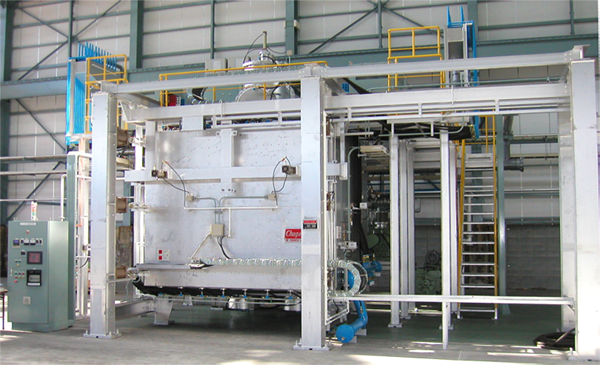

Thermal Technology Thermal Technology

We provide the thermal technology required by our customers by combining various processes such as thermal control with production equipment that can freely shape the processing environment, including high temperature, high pressure, vacuum, and atmosphere.

Total Engineering Total Engineering

We customize production equipment to meet the customer's environment and provide technology that is friendly to both the customer and the earth through designs that not only satisfy functionality as a production system, but also consider operability and energy conservation.

Advanced Technology State-of-the-art technology

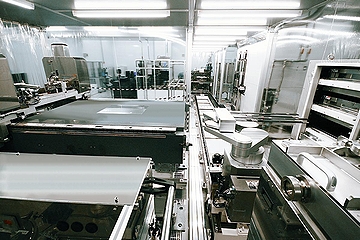

In IT, electronics, and other facilities requiring clean environments and high-precision controllability, we develop new and unique technologies by introducing state-of-the-art technologies to meet the diversifying needs of our customers.

core technology

Supported by fundamental technologies developed over many years

By deepening and integrating original core technologies,

We provide society with innovative technologies that create a prosperous future for people and the Earth.

-

Combustion

Technology that combines various solid, liquid, and gaseous fuels, oxygen, and ignition sources to freely form flames and create optimal temperature ranges and atmospheres.

-

Electric Heat

Technology to create optimal temperature ranges and atmospheres by selecting heater materials and devising shapes and layouts.

-

Heating and Cooling

Technology to manipulate heat by making full use of radiation heat transfer, convection heat transfer, and heat conduction to change the temperature of an object at will.

-

Atmosphere Control

Technology to control the atmosphere to suit the material processing process, using air, exhaust gas, or special gases (hydrogen, carburizing gas, etc.)

-

Customize

Technology to propose and design equipment to meet customer requirements, including scale-up for mass production, etc.

-

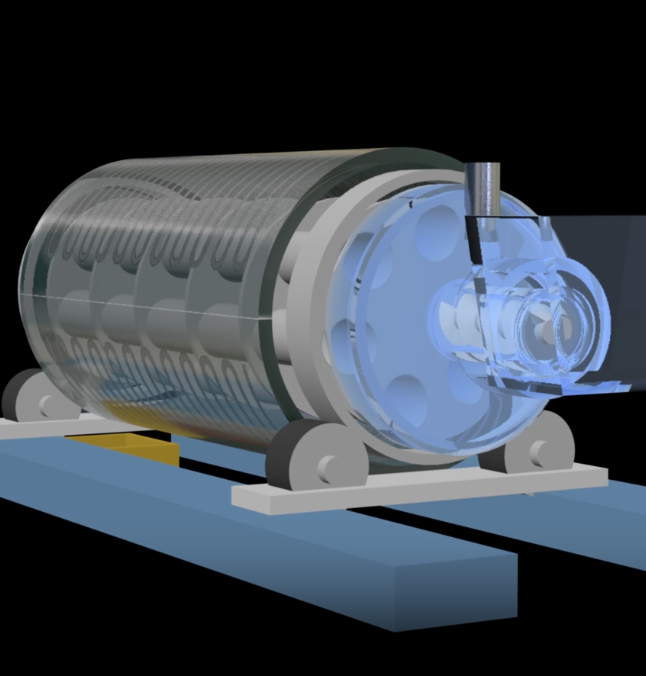

Pressurization and Vacuum

Technology to create pressure fields from vacuum to 9.9 MPa, tailored to the material processing process

-

Maintenance

Technology that responds quickly and carefully to requests for after-sales service, etc., with a design that takes maintainability into consideration and service bases spread throughout the country.

-

Manufacture

Technology to provide high quality products with short delivery times through a fusion of design and manufacturing based on years of experience and achievements.

-

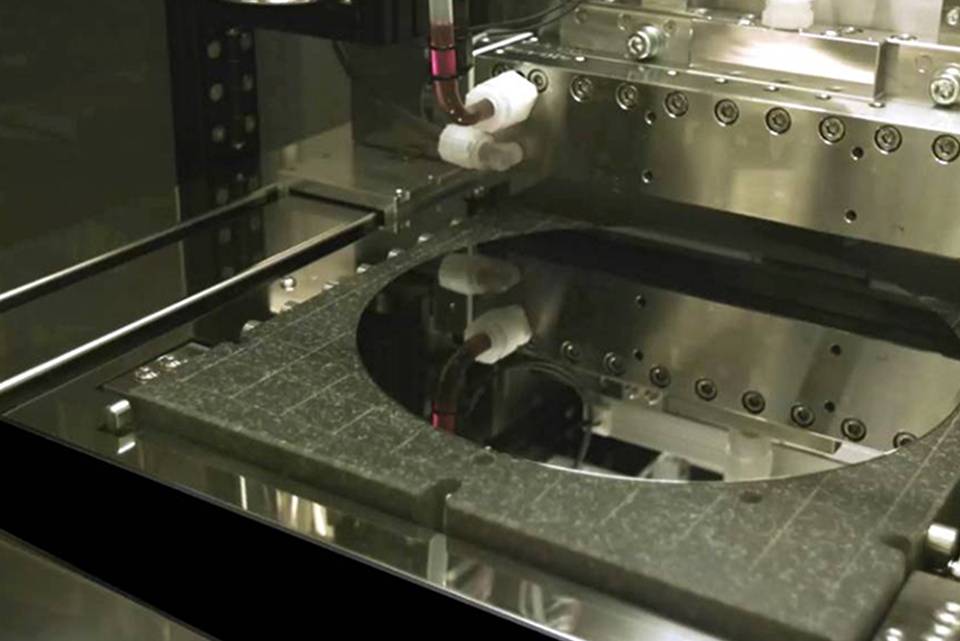

Clean

Technology that creates a clean processing environment and controls foreign matter contamination of materials to an extremely low level

-

Thermal Control

Technology to raise or lower the temperature of an object at an appropriate rate or to control temperature distribution uniformly, from below freezing to 3000°C

-

Energy-saving

Technology that contributes to the reduction of greenhouse gas emissions by eliminating wasteful energy consumption through high-efficiency combustion, reduced heat dissipation, and exhaust heat recovery.

-

Analysis

Technology for new product development and customization through simulation that combines theory and experience

-

Automation

Technology to reduce labor and improve safety by automating material and product transfer, process control, and equipment monitoring

-

Coating

Technology for thin, precise coating of various coating liquids of low to high viscosity on steel plates, substrates, and films

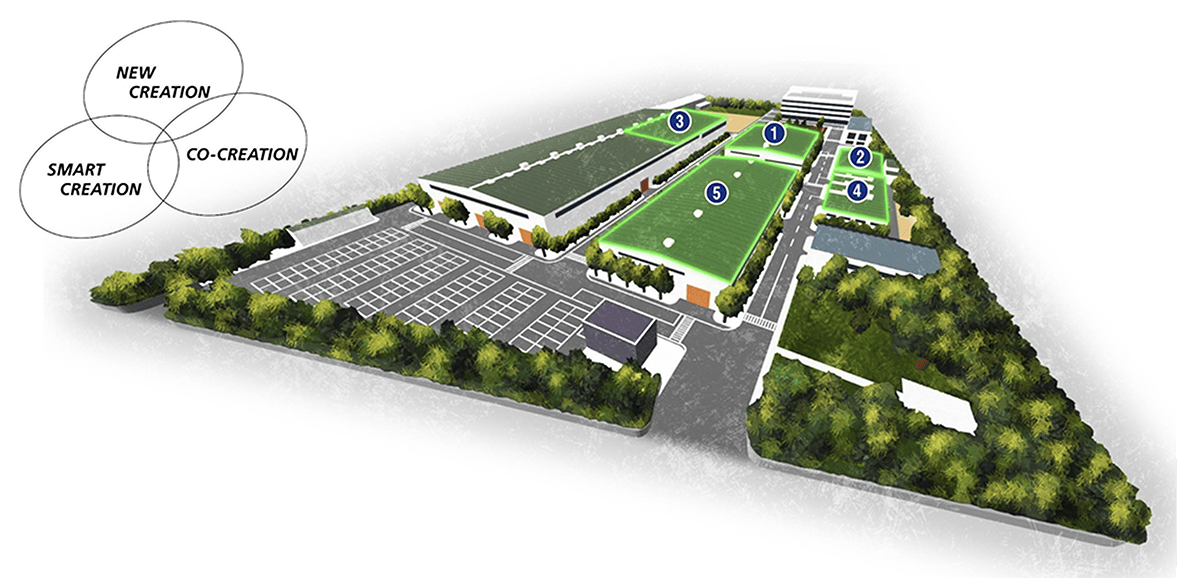

Thermal Technology Creation Center

Evolved into an innovation center by integrating research and development functions.

Thermal Technology Leading the World to a New Dimension

The role of thermal technology is becoming increasingly important in the development of CO₂ emission-free combustion technology to achieve carbon neutrality, the development of heat treatment equipment for EVs, secondary batteries, and semiconductor materials, and the innovation of existing thermal technology to meet customers' new product development and production needs. In order to maximize the potential of thermal technology, our core technology, and meet these needs, Chugai Furnace Manufacturing will integrate its various research and development functions into the Sakai Works in November 2023. We will accelerate innovation through co-creation with members and partners inside and outside of Japan, and contribute to the creation of a sustainable society.

Test equipment is also available for customers who are in talks to install equipment,

It is useful for R&D testing of treatment processes, equipment specifications, and performance evaluation.