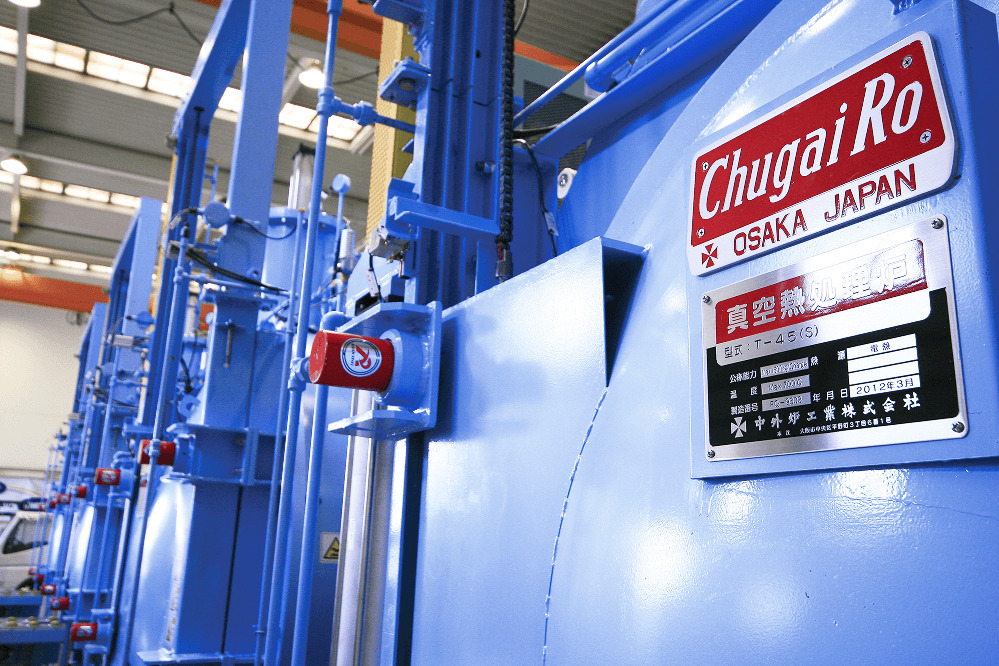

Heat Treatment Furnaces for Parts & Materials

Parts and

Materials Heat Treatment Furnace

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

The die head is equipped with a unique width-changing mechanism! Applicable to various shapes of coating regardless of substrate shape.

Heat Treatment Furnaces for Parts & Materials

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

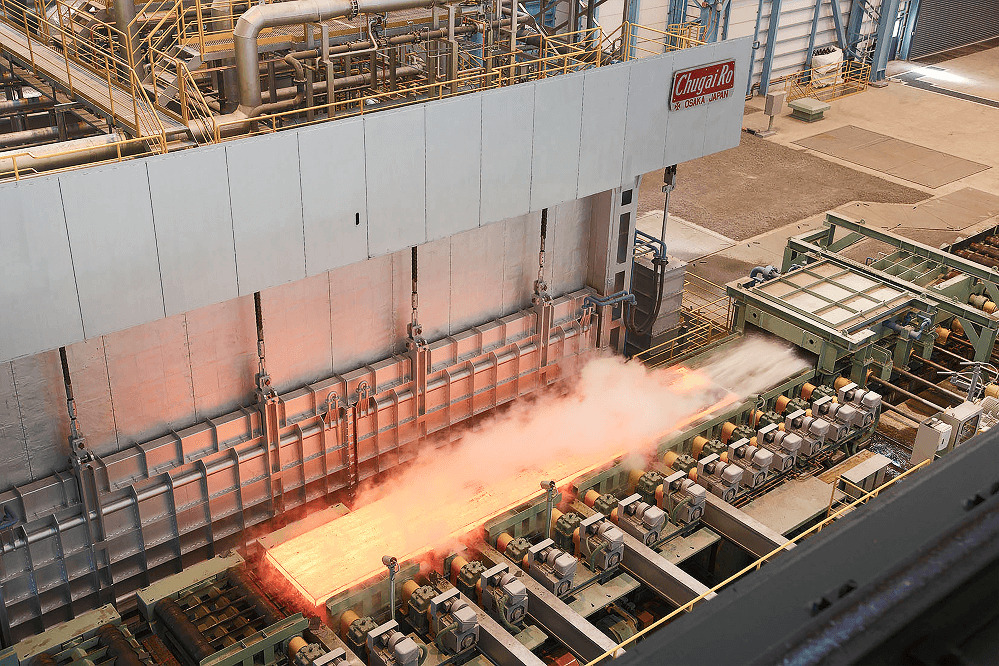

Plant for Steels & Non-Steel Metals

Large-scale heating furnaces, large-scale heat treatment furnaces, transverse induction heating equipment

Burner & Combustion Control Equipment

Hydrogen burners, oil and gas burners, gas burners

Substrate, Film Coating & Drying Equipment

Heat treatment equipment, precision coatings

Air Pollution Control System

Thermal storage-type exhaust gas treatment system, direct combustion type (direct combustion type), maintenance

Kiln & Environmental Equipment

Multi-tube Rotary Kiln Carbonization System

You can download catalogs in PDF format about Chugai Ro's products and services.

Please use it for sharing and collecting information about the company.