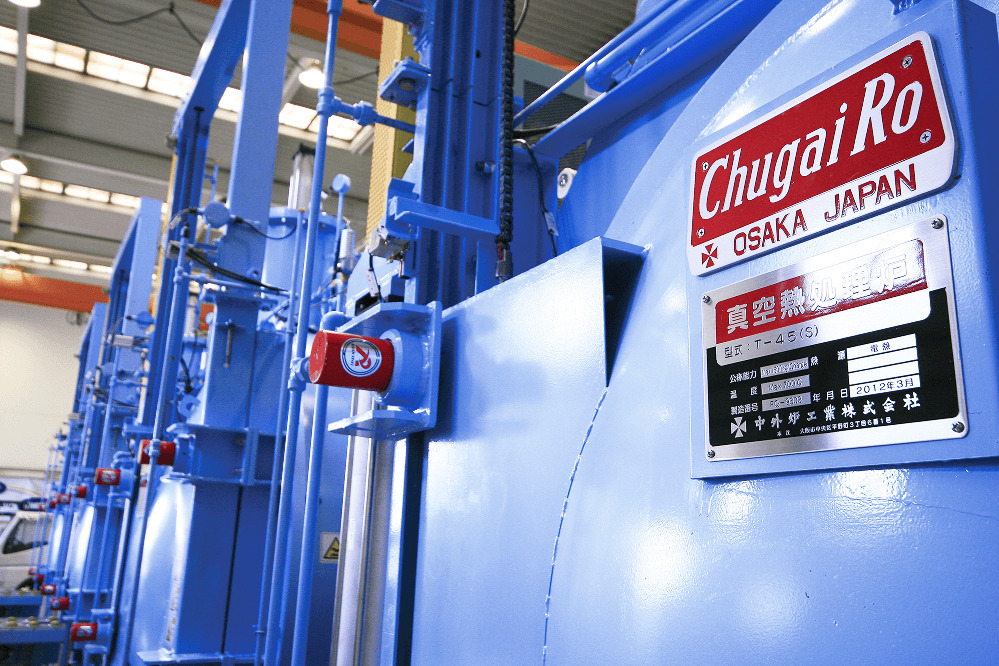

Heat Treatment Furnaces for Parts & Materials

Parts and

Materials Heat Treatment Furnace

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

By harnessing high-temperature superheated steam produced through hydrogen and oxygen combustion, this new heating technology achieves zero CO₂ emissions.

| Equipment Features |

What is superheated steam?Superheated steam is a colorless, transparent steam gas that is produced by continuing to heat saturated steam after it has evaporated at 100°C.

1. Superheated steam is generated through the combustion of hydrogen and oxygen (no heater required). 2. The process produces superheated steam at 1,700°C. 3. Flames with zero CO₂ emissions contribute to industrial evolution. |

|---|---|

| Equipment Features and Advantages |

1. It enables processing at low to ultra-high temperatures ranging from 200 to 1,700°C.This achieves ultra-high-temperature processing that exceeds the capabilities of electric superheated steam generators. 2. The high heat transfer performance enables quick, uniform heating.At lower temperatures, the material is rapidly heated by the latent heat of the condensation released when superheated steam changes to water, whereas at higher temperatures, heating is achieved through the high radiative heat transfer of steam. 3. Steam-driven carbon gasification reaction at temperatures above 800°CIn a superheated steam atmosphere exceeding 800°C, carbon released

from the treated material undergoes a steam gasification reaction*, enabling the decomposition of organic solvents, resins, and similar substances without self-ignition, even in an oxidizing environment. 4. It enables heating in both oxidizing and non-oxidizing atmospheres.By adjusting the hydrogen-oxygen ratio, the atmosphere inside the furnace can be switched from oxidizing to non-oxidizing and vice versa.

|

| Example Applications |

Superheated steam offers a wide range of benefits depending on the treated material.

An example of superheated steam put to effective use ・Thermal treatment of spent lithium-ion batteries from vehicles

Organic solvents in the electrolyte and resin in separators pose a risk of thermal runaway due to reactions with oxygen at high temperatures. However, they can be safely decomposed through the steam gasification reaction of superheated steam, which prevents them from reacting with oxygen. |

| Hydrogen-oxygen combustion superheated steam testing systems |

Chugai Ro is equipped with hydrogen-oxygen combustion superheated steam testing systems and provides testing support for those adopting equipment.

What Hydrogen-Oxygen Combustion Flame Looks LikeThe amount of superheated steam can be adjusted by introducing sprayed water in addition to the exhaust gas from hydrogen combustion.

|

Heat Treatment Furnaces for Parts & Materials

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

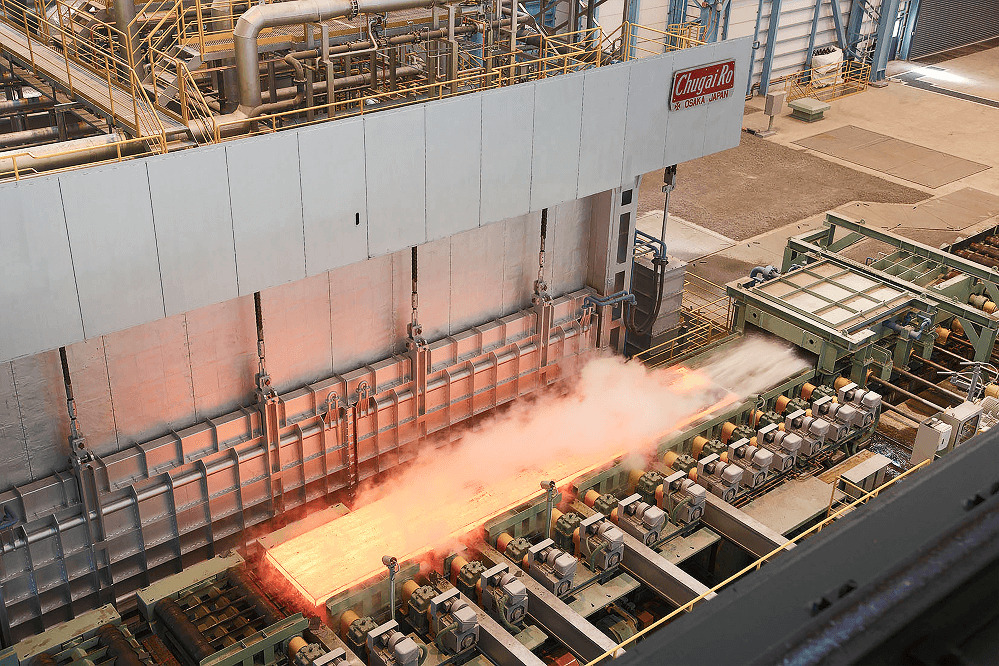

Plant for Steels & Non-Steel Metals

Large-scale heating furnaces, large-scale heat treatment furnaces, transverse induction heating equipment

Burner & Combustion Control Equipment

Hydrogen burners, oil and gas burners, gas burners

Substrate, Film Coating & Drying Equipment

Heat treatment equipment, precision coatings

Air Pollution Control System

Thermal storage-type exhaust gas treatment system, direct combustion type (direct combustion type), maintenance

Kiln & Environmental Equipment

Multi-tube Rotary Kiln Carbonization System

You can download catalogs in PDF format about Chugai Ro's products and services.

Please use it for sharing and collecting information about the company.