Contract Testing Heating test with superheated steam at ultra-high temperature

Heating test with superheated steam at ultra-high temperature

- Test theme name

- Heating test with superheated steam at ultra-high temperature

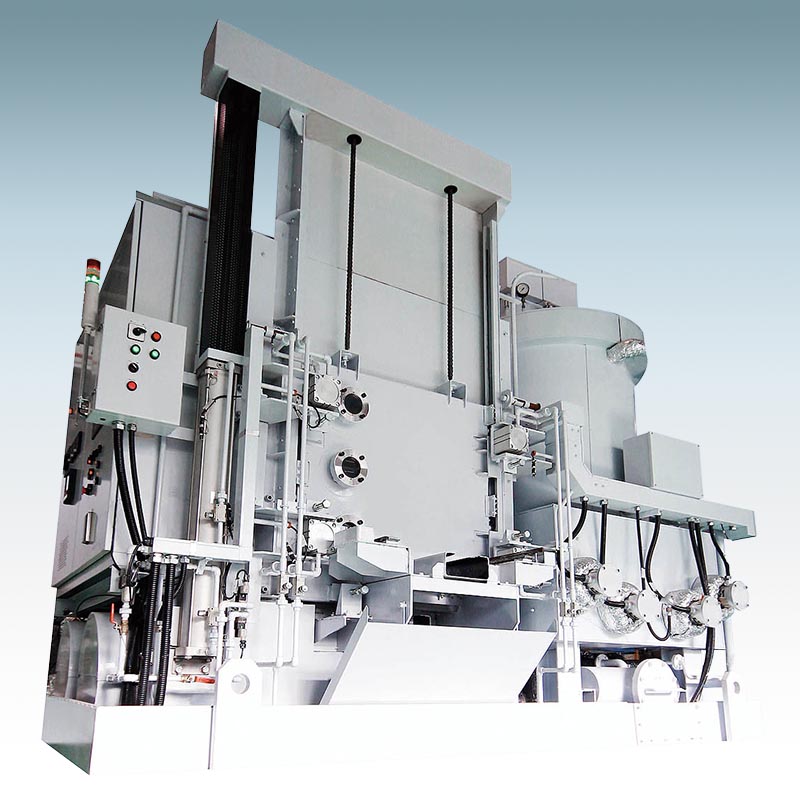

- Test Equipment Name

- Ultra High Temperature Superheated Steam Test Equipment

- Equipment Specifications

Equipment Features Patent pending.

We have developed a heat treatment furnace capable of high-temperature treatment for industrial use in order to expand the use of superheated steam, which is already being used in the food and low-temperature fields.- Furnaces capable of generating superheated steam at very high temperatures

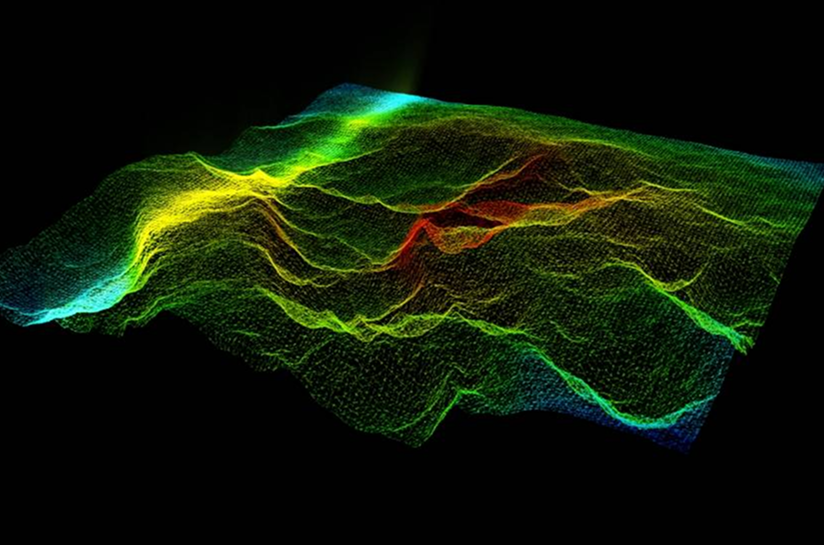

- The characteristics of superheated steam enable 1) uniform heating, 2) rapid heating, and 3) oxygen-free heating.

- By applying Chugai's hydrogen combustion technology, heat treatment with superheated steam at ultra-high temperatures of 1,000°C or higher, which has been difficult to achieve in the past, is possible.

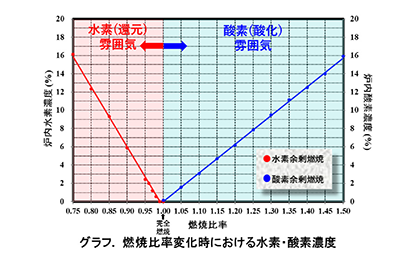

- Oxygen-free, oxidizing, and hydrogen-reducing atmospheres are also possible under superheated steam atmosphere by our unique combustion control developed through years of combustion technology.

- CO₂-free heating system with hydrogen and oxygen combustion.

- Since H₂O gas generated from hydrogen and oxygen is used, superheated steam heat treatment is possible with minimal impurities.

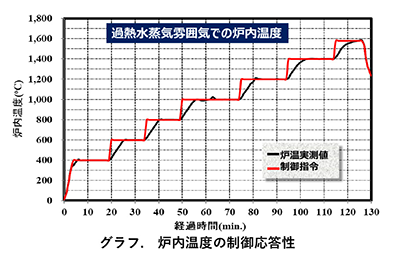

Furnace temperature control response

Hydrogen and oxygen concentrations during combustion comparison change

Use - Reduced processing time for degreasing and sintering processes in ceramic products

- Thermal treatment of waste batteries for recycling Detoxification, carbonization, gasification

- Uniform heat treatment of functional powder materials

- Degreasing treatment/rapid heating treatment of metals

- CFRP recycling heat treatment

- Degreasing/baking treatment of electronic components

- Carbonization/decomposition treatment of resins (plastics)

- Aqueous gasification reaction with endothermic reaction, etc.

Equipment Specifications Test material dimensions 150mmW × 150mmL × 50mmH or less Temperature range 200-1600°C (furnace temperature) Furnace atmosphere Oxygen concentration in the furnace 0 to 25% (oxidation) or Hydrogen concentration in the furnace 0% to 10% (reduction) Steam input Max. 19kg/h (water equivalent) *Depends on furnace internal temperature

Regarding test registration

Please fill out the form below to give us an overview of your project.

- Purpose

- Processing material(Product name, dimensions, and mass and material)

- Volume

- Target quality

- Heat treatment conditions

- Preferred time of year

- Testing is generally paid for.

- After test details are finalized, we will submit a quotation.

- If you wish to apply for the test, please fill out the form below and submit it.

- Please note that we may decline your request, or we may not be able to meet your requested time frame due to equipment usage conditions. Please understand this in advance.

- Chugai Ro Co., Ltd. prepares test equipment for customers that are thinking of introducing our equipment

- Please note that we do not accept any charge processing or independent testing.

Chugai Ro Co., Ltd. prepares test equipment for customers that are thinking of introducing our equipment

You can use the form from the link below for inquiries, applications, etc.

Click here to apply