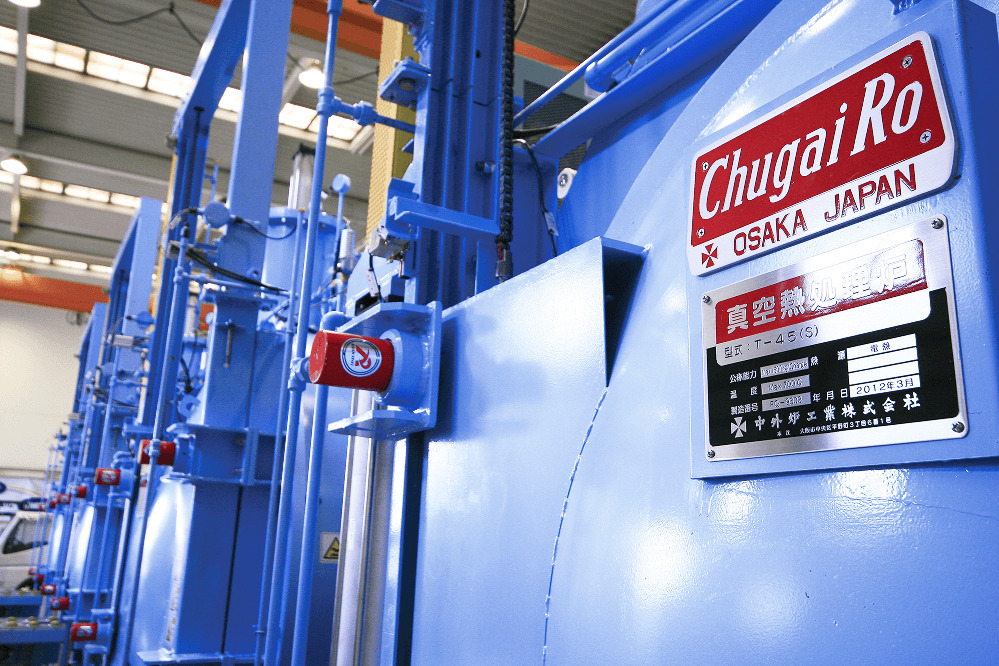

Heat Treatment Furnaces for Parts & Materials

Parts and

Materials Heat Treatment Furnace

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

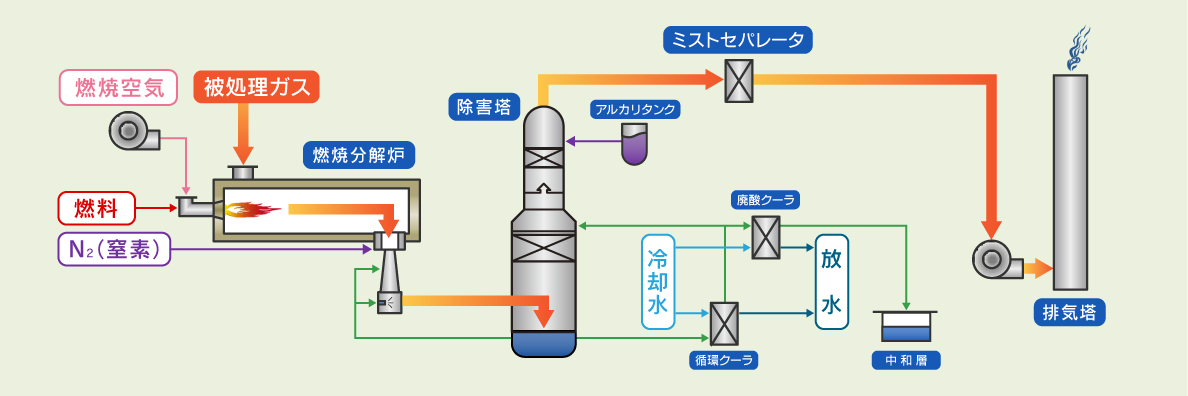

The entire system, including the combustion furnace, is controlled by negative pressure, making it a safe and reliable incineration facility.

| Use |

Detoxification of organic compounds containing chlorine and fluorine Decomposition of multi-substance gas mixtures |

|---|---|

| Characteristics |

Long life and safety design with no leakage outside the facility system

High decomposition rate equipment

Prevents dioxin resynthesis

Acids can be recovered

Select the best material in consideration of heat resistance and material to be processed.

Easy inspection and maintenance

|

| System Flow |

Chlorine- and fluorine-containing waste gas and liquid waste incineration facilities |

Heat Treatment Furnaces for Parts & Materials

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

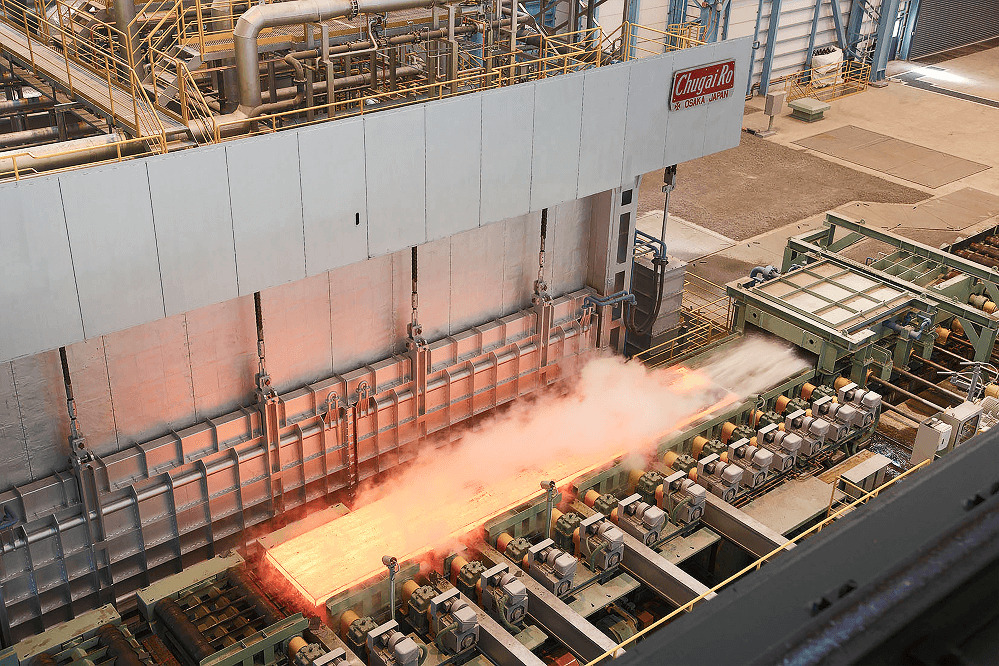

Plant for Steels & Non-Steel Metals

Large-scale heating furnaces, large-scale heat treatment furnaces, transverse induction heating equipment

Burner & Combustion Control Equipment

Hydrogen burners, oil and gas burners, gas burners

Substrate, Film Coating & Drying Equipment

Heat treatment equipment, precision coatings

Air Pollution Control System

Thermal storage-type exhaust gas treatment system, direct combustion type (direct combustion type), maintenance

Kiln & Environmental Equipment

Multi-tube Rotary Kiln Carbonization System

You can download catalogs in PDF format about Chugai Ro's products and services.

Please use it for sharing and collecting information about the company.