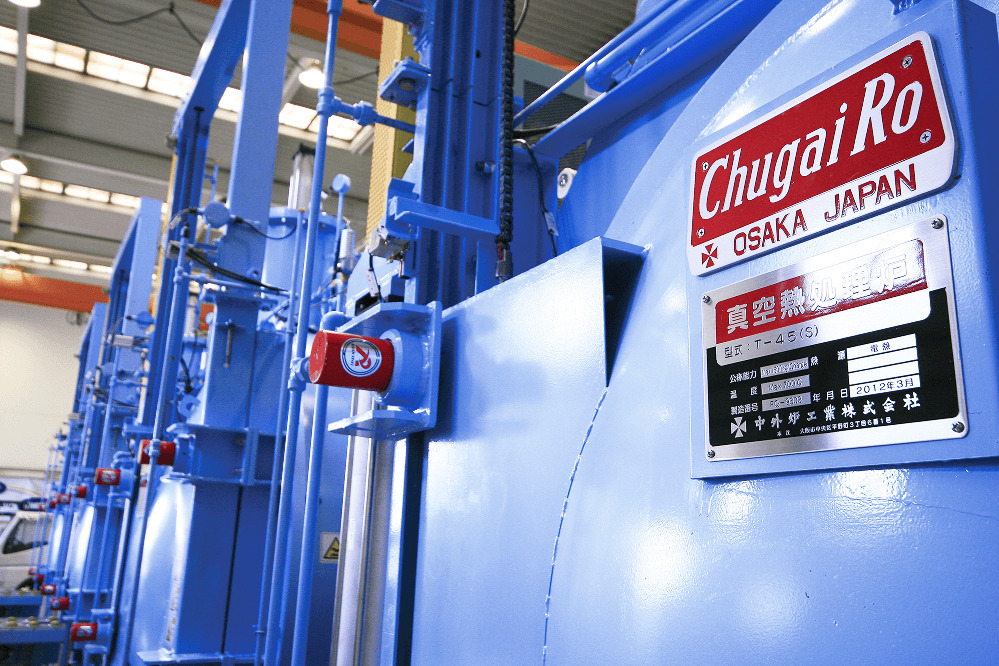

Heat Treatment Furnaces for Parts & Materials

Parts and

Materials Heat Treatment Furnace

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

Diffusion combustion oxygen flame! Variable flame shape! Variable oxygen concentration!

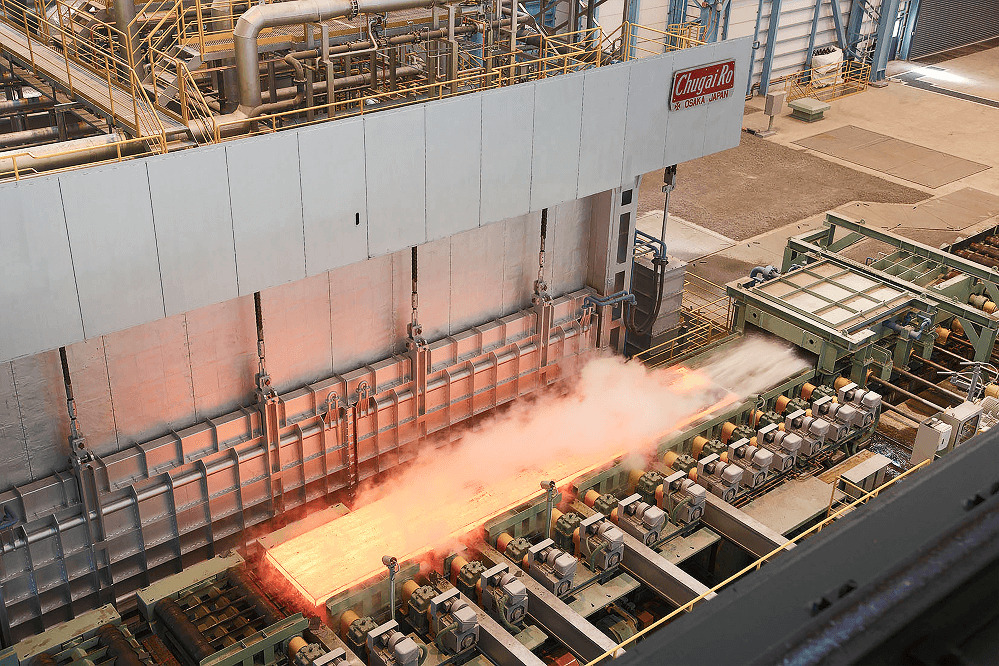

| Product Overview | This preheating system uses an oxygen burner to preheat the tundish in continuous casting equipment in the steelmaking process, achieving higher energy savings compared to preheating with a conventional air burner. The use of oxygen burners offers the following advantages

This system consists of our original diffusion combustion oxygen burner, optimum combustion control system, drive unit, control piping equipment, and control panel. |

|---|---|

| forte |

|

| Advantages |

|

Heat Treatment Furnaces for Parts & Materials

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

Plant for Steels & Non-Steel Metals

Large-scale heating furnaces, large-scale heat treatment furnaces, transverse induction heating equipment

Burner & Combustion Control Equipment

Hydrogen burners, oil and gas burners, gas burners

Substrate, Film Coating & Drying Equipment

Heat treatment equipment, precision coatings

Air Pollution Control System

Thermal storage-type exhaust gas treatment system, direct combustion type (direct combustion type), maintenance

Kiln & Environmental Equipment

Multi-tube Rotary Kiln Carbonization System

You can download catalogs in PDF format about Chugai Ro's products and services.

Please use it for sharing and collecting information about the company.