Heat Treatment Furnaces for Parts & Materials

Parts and

Materials Heat Treatment Furnace

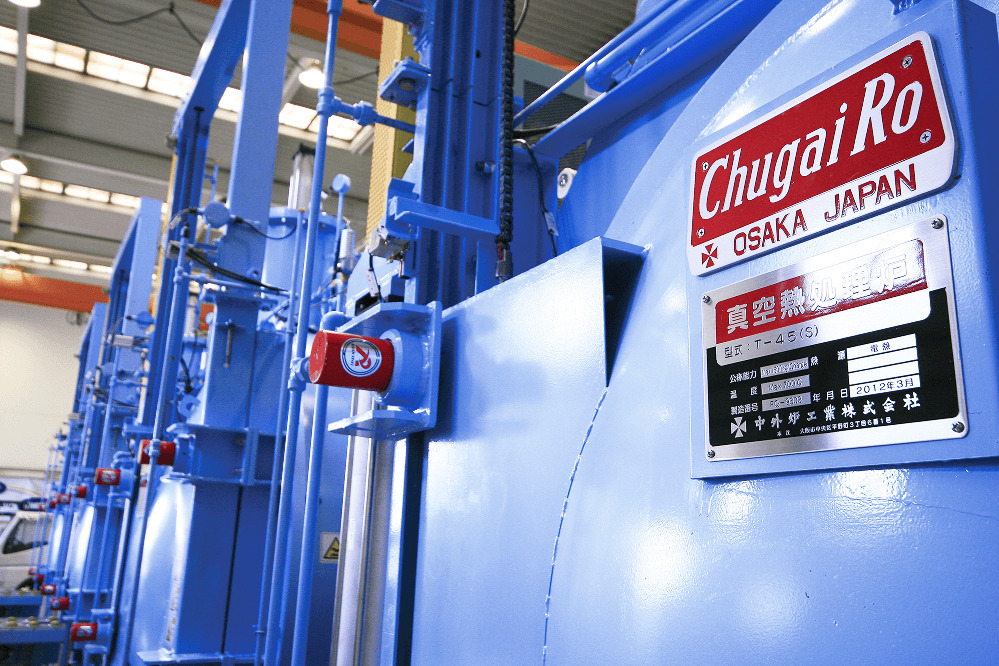

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

Contributes to an increase in steel output, reduction of electricity consumption rate, and shortening of work hours!

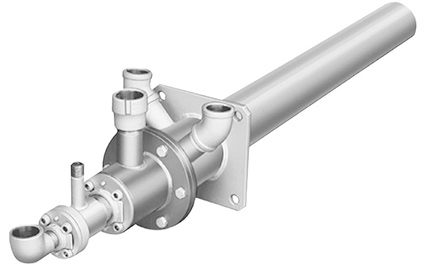

Oxygen burners for auxiliary fuel of electric arc furnaces accelerate arc melting and contribute to increased steel output, reduced power consumption, and shorter working hours. The CTB-I model is exclusively for auxiliary fuel, while the CTB-II model can be used for both auxiliary fuel and oxygen injection. The OXB and OXF models are also available for fixed mounting on the furnace body. We also have abundant experience in the total design and production of arc furnace auxiliary fuel systems, which have been well received.

Fuel: various oils and gases, pulverized coal

Combustion volume: 3140-16280 kW

Oxygen content: 600-1600 m3/h (combustion)

200-1600m3/h (blown in)

Heat Treatment Furnaces for Parts & Materials

Vacuum furnaces, high-temperature furnaces/hot presses, vacuum carburizing, heat treatment of functional materials

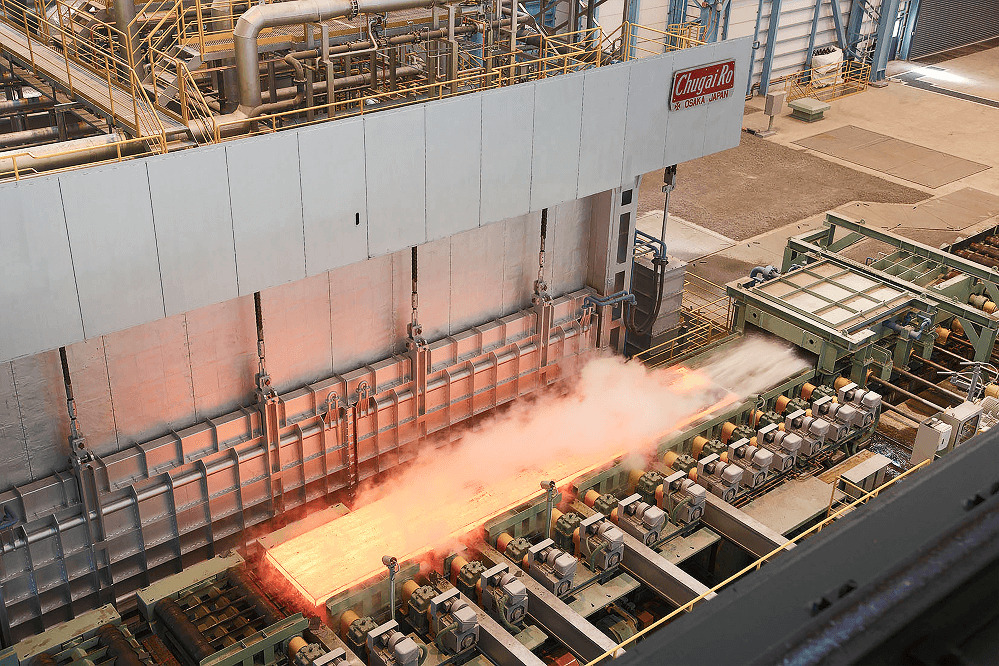

Plant for Steels & Non-Steel Metals

Large-scale heating furnaces, large-scale heat treatment furnaces, transverse induction heating equipment

Burner & Combustion Control Equipment

Hydrogen burners, oil and gas burners, gas burners

Substrate, Film Coating & Drying Equipment

Heat treatment equipment, precision coatings

Air Pollution Control System

Thermal storage-type exhaust gas treatment system, direct combustion type (direct combustion type), maintenance

Kiln & Environmental Equipment

Multi-tube Rotary Kiln Carbonization System

You can download catalogs in PDF format about Chugai Ro's products and services.

Please use it for sharing and collecting information about the company.