Maintenance, Energy-saving, Support Maintenance, energy saving and improvement support

Chugai Ro Co., Ltd. offers maintenance support for delivered products and improvement of problems in each field.

Please feel free to ask us anything, even the smallest detail. We will make a proposal.

Safety Measure

Thorough safety management minimizes risk.

Ultravision installation on burner

Furnace management

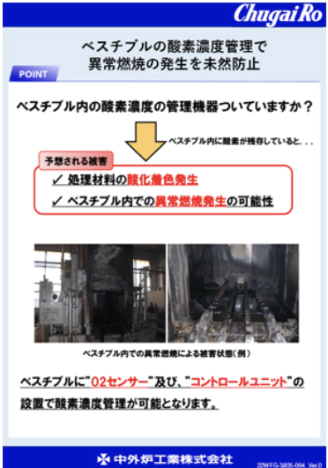

- O₂ concentration control in vestibules

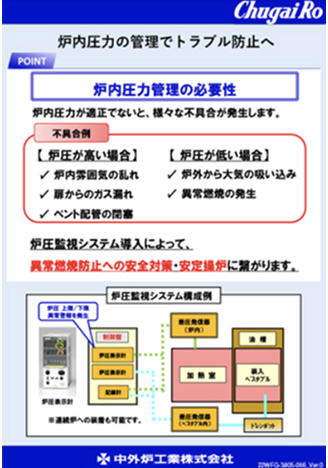

- Furnace pressure control

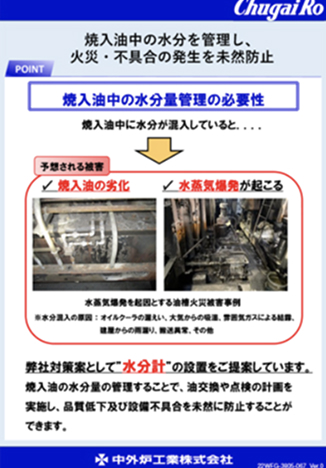

Control of quenching oil

- Moisture content in oil

Disaster prevention measures

- Power Outage Countermeasures

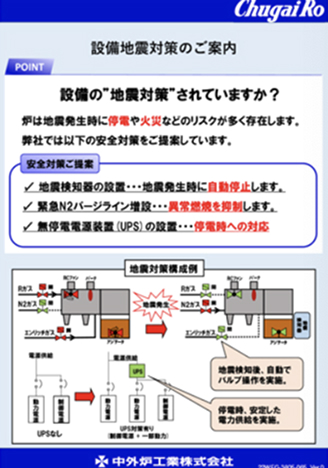

- Earthquake Countermeasures

Decarbonization Proposal

To contribute to the reduction of greenhouse gas emissions

Accelerate efforts

Burner to heater replacement

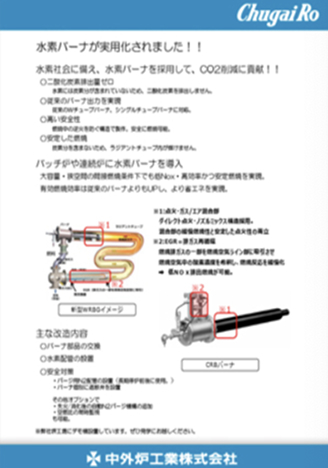

Introduction of hydrogen burners

Introduction of ammonia burner (under development)

Fuel switching

- LPG to natural gas

- From kerosene and heavy oil to natural gas

- Propose various energy-saving devices and solutions

Other decarbonization technologies

Related Content

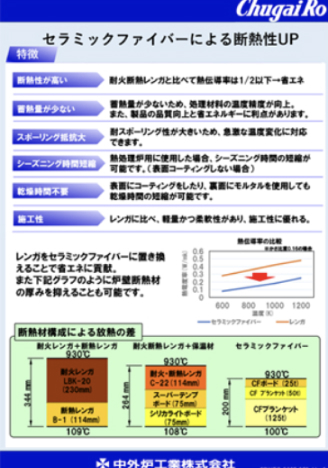

Energy Conservation and Retrofitting

Improved cost-effectiveness

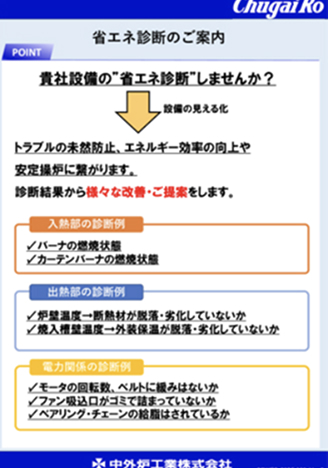

Energy-saving diagnosis

- We survey the energy usage of your facilities and propose the most cost-effective energy-saving modifications.

Energy-saving modifications (heat loss reduction)

- Insulation from bricks to ceramic fiber

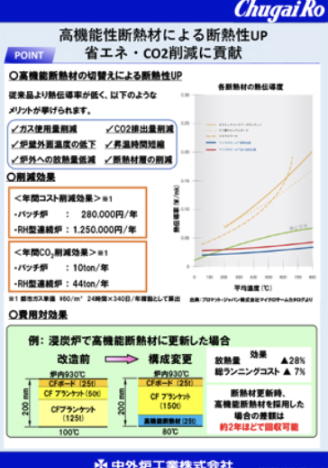

- Use of high-performance insulation

- Conversion of ▪RC fan from water-cooled structure to air-cooled

Energy-saving modification (combustion efficiency improvement)

- Burner efficiency improved by using a recuperator

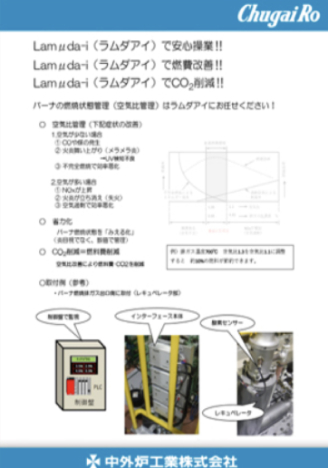

- Exhaust gas O₂ monitoring

- Automatic Air Ratio Controller (EBC³™)

- High-efficiency recycle burner

- Conversion to Regenerative Burner

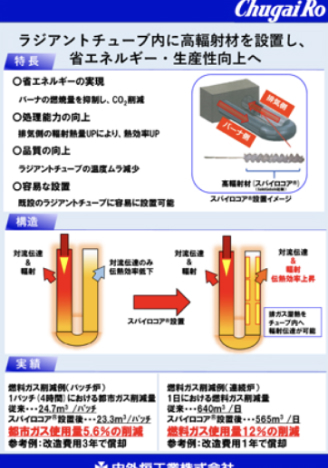

- Replace with high-efficiency radiant tube burner

- Optimization of burner combustion by installation of ▪O₂ sensor

- Review of curtain burner operation

- Review of ▪R gas generation

Power Reduction

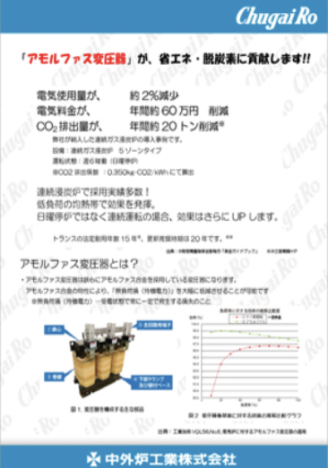

- Power saving by using amorphous transformers

- High-efficiency motors

- Inverter

Functional and Productivity Improvements

Visualization and status display and condition monitoring can be entrusted to us.

Status display on touch panel

- Insulation condition monitoring with ▪ thermography

- ▪IoT (CRism)

- Constant measurement of exhaust gas O₂

- Individual fuel gas usage measurement

Improved maintainability

- ▪RC fan jacket air cooling

- Photoelectronization of ▪ indexes

Increased Productivity

- Reduction of seasoning time = review of operational methods

- Reduction of cycle time = increased RC fan speed

- Reduction of cleaning solution consumption and cycle time for vacuum cleaning equipment

Related Content

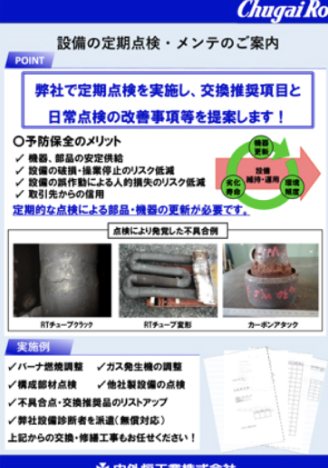

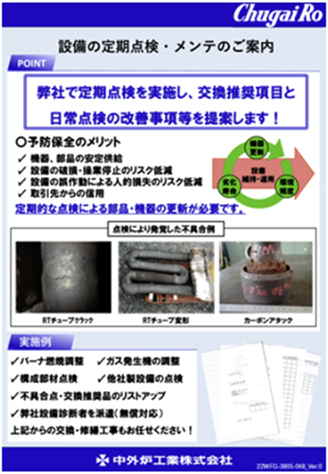

Preventive maintenance and inspection

Reduced risk of low utilization and unforeseen problems

Perform periodic maintenance and inspections

- Preventive maintenance, deterioration diagnosis

- Proposal for planned component renewal

- ▪ Suggestions for maintaining good operating conditions

- Confirmation of discontinued products and proposal of successor models

IoT (CRism) implementation for condition monitoring

Manpower-saving Proposal

Even when not on site, equipment monitoring and

Can be managed and operated

Equipment condition monitoring

- Remote Monitoring

- Batch data management and graphing

Equipment Automation

- Automatic start-up and shut-down

- Automatic transfer (complete set including transfer equipment proposed)

Related Content

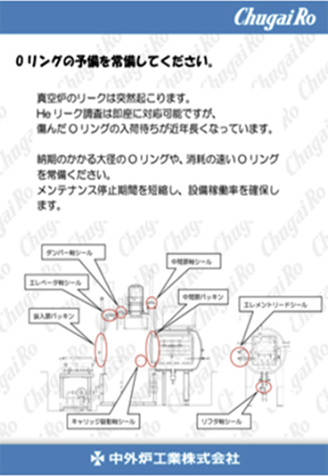

Spare Parts Sales

Sales of spare parts necessary for stable operations

Stable, low-cost supply due to large volume procurement

Some of our products are stocked at our factory and can be provided in a timely manner.

Relocation and Disposal

Support from research and planning

Relocation and disposal plan including asbestos content survey

Equipment layout review and rearrangement

Equipment Disposal and Industrial Waste Disposal

Relocation from Japan to overseas

Repair and Refresh

Prevention to improve productivity

Insulation renewal and repair

Replacement of furnace parts (burners, heaters, impellers, etc.)

Maintenance of vacuum and high temperature furnaces

Renewal of control panels and electrical instrumentation

Update valve stand

Piping routing and relocation

Renewal of other aging areas and obsolete items

- Proposals for energy conservation, improvement, and safety of delivered equipment

- Planning of repair work and purchase of spare parts based on preventive maintenance

- Maintenance support for other companies' equipment

- Relocation, removal, and refreshment

- Please contact us for any other inquiries.

For example...

- The motor needs to be replaced, but it doesn't look like it can be installed as is...

- I need to replace a bearing, but I don't have the documentation and don't know the model number...

- The burner keeps misfiring, but I don't know how to adjust it...

- I want to install a touch panel to visualize, but the equipment is old...

- I want to replace the insulation with high-efficiency ones, but I don't know where to go for help...

- My analyzer is acting up, but I don't know how to calibrate it...

- I want to increase the processing temperature of the material, but I don't know if I can ...

- We are being asked to take energy conservation measures, but we don't know where to start...

- We want to make it easier to manage our facilities...

- I want to improve the efficiency of my daily work...

Do you have any problems?

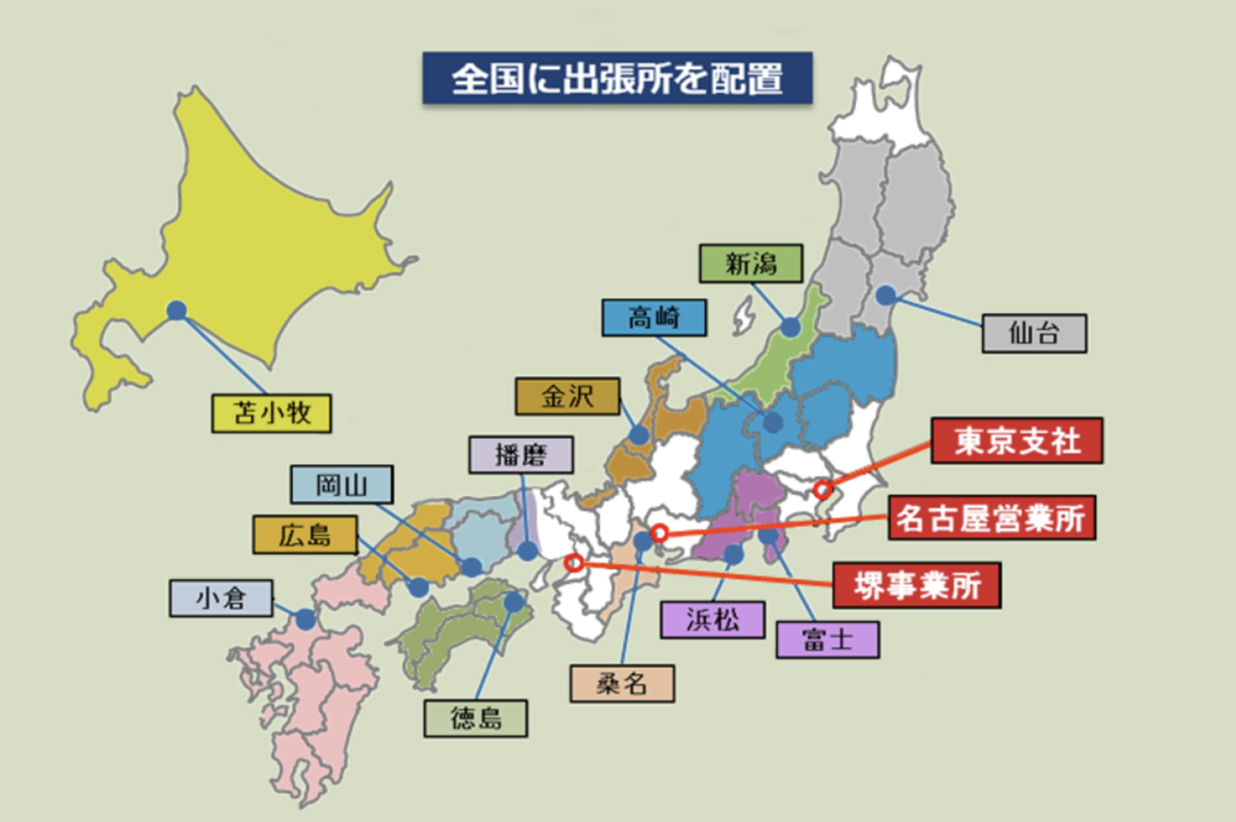

In addition to each sales office, 13 branch offices are located throughout Japan to ensure a quick response,

We are continuing to develop the system by properly assigning construction SVs to each of them.

We are happy to discuss any details or other company's products with you.

We will be happy to make suggestions.

Click here to apply