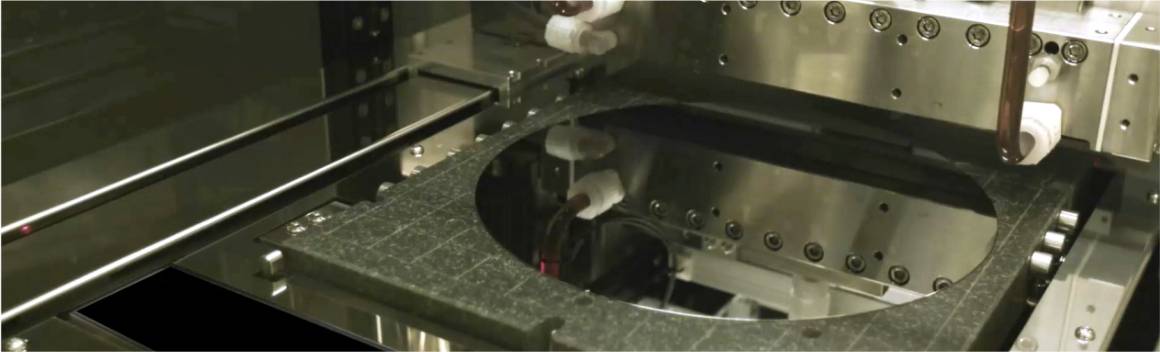

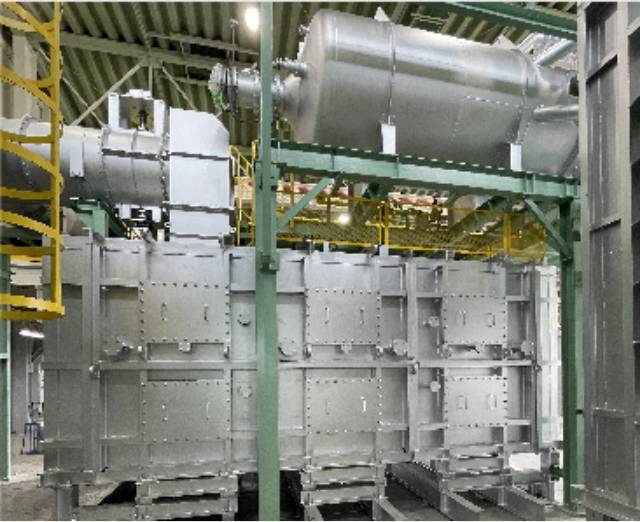

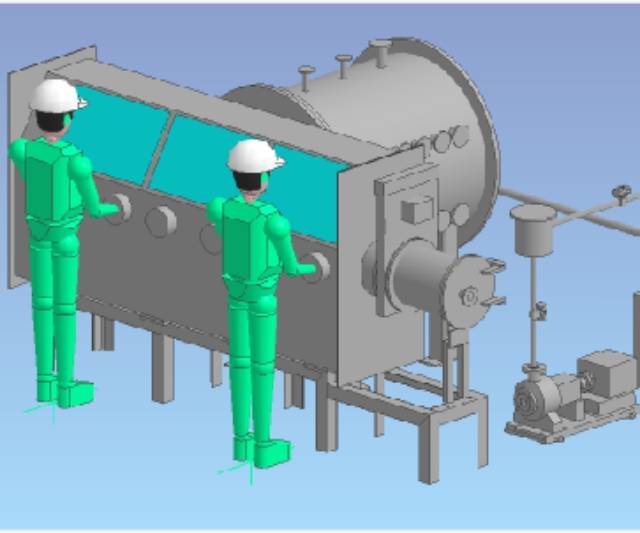

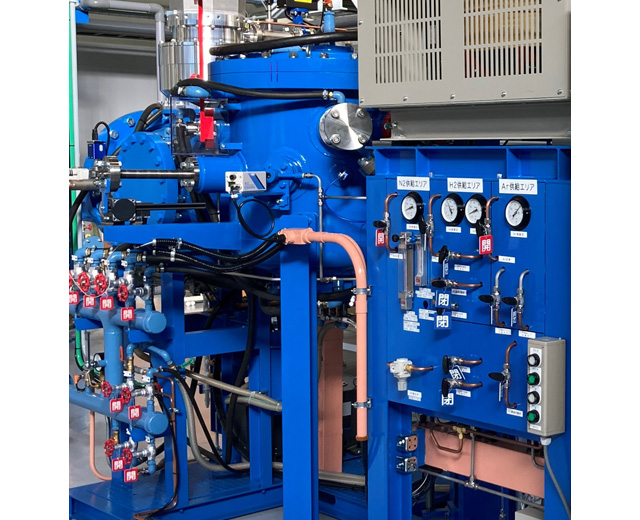

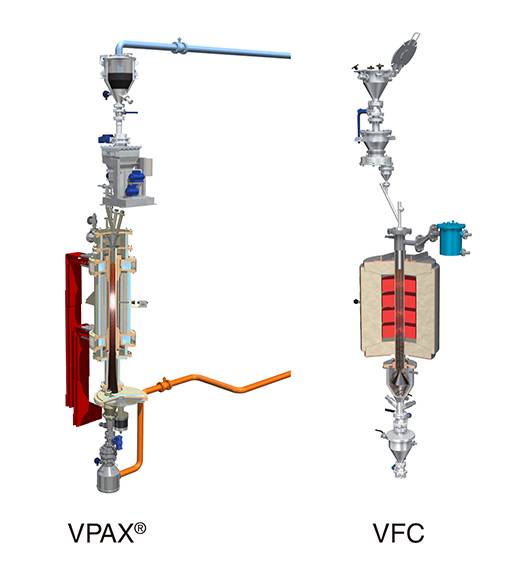

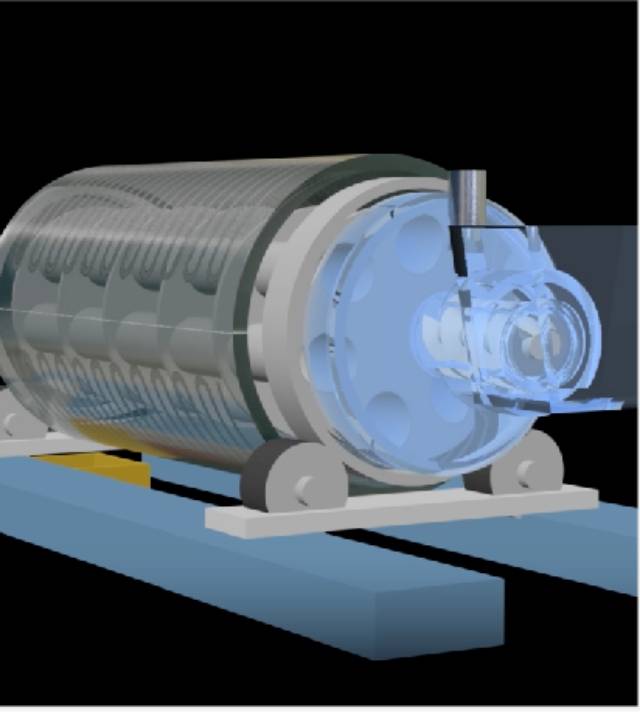

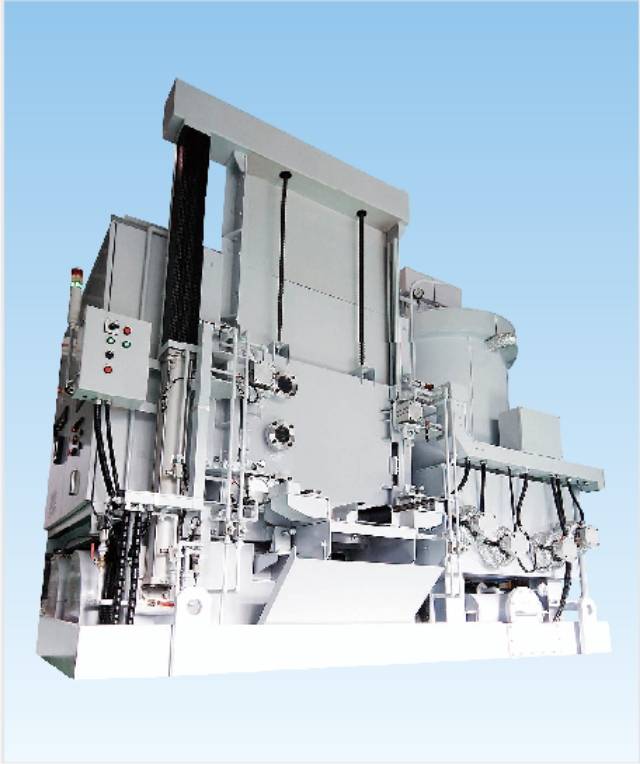

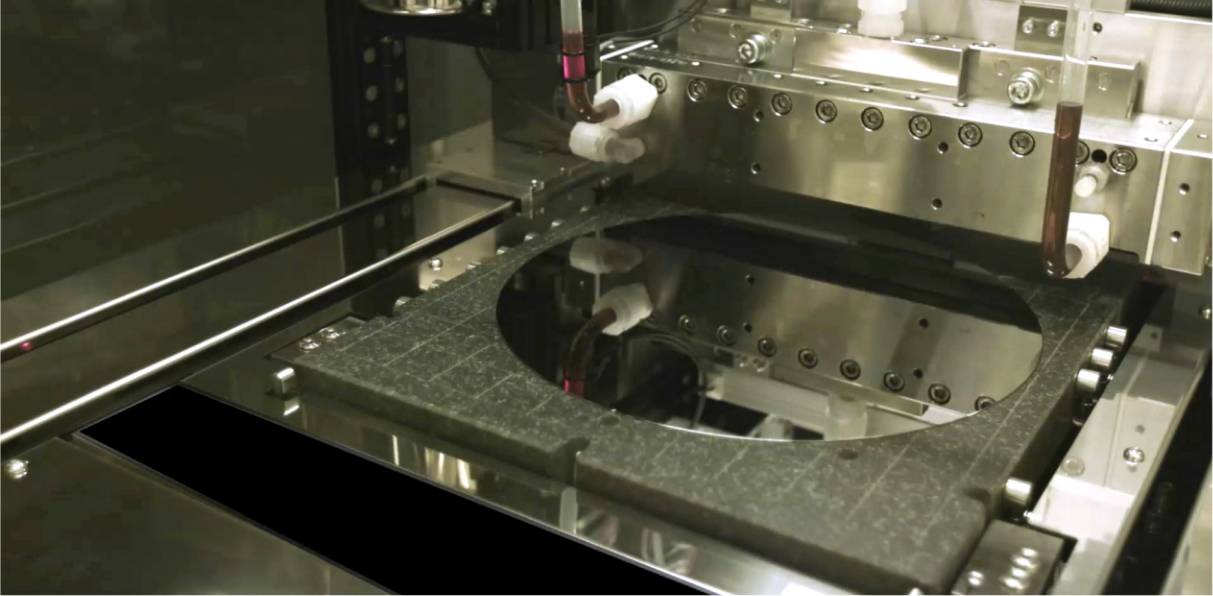

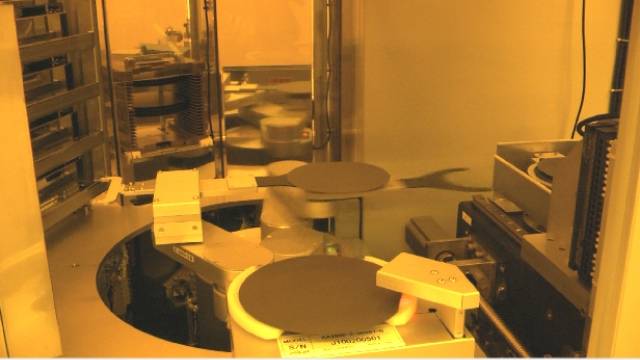

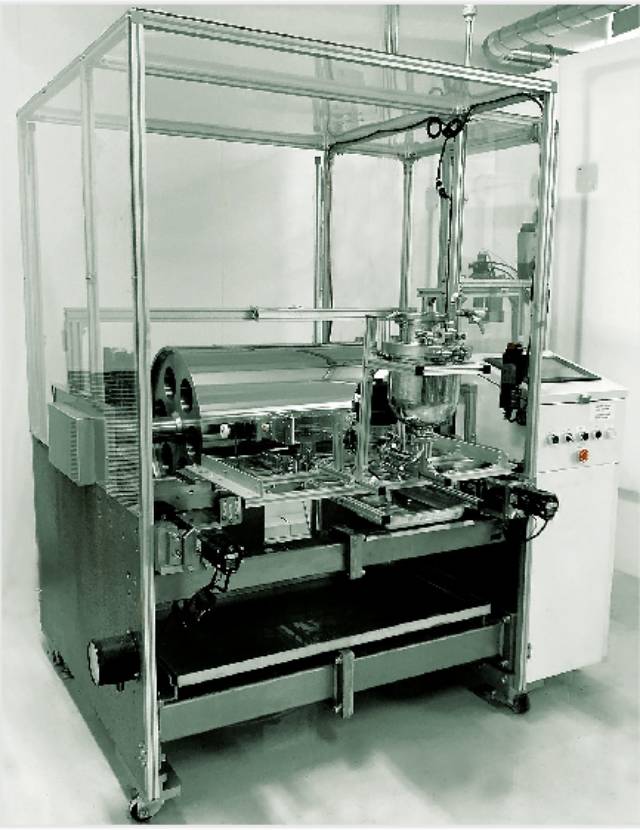

Core facilities that play a central role in innovation creationThermal Technology Creative Center

Our central facilities for research and development have been established to strengthen our research and development capabilities, boost joint development with members both inside and outside the company, and practice actively and rapidly "New Value Creation," as stated in the management philosophy.