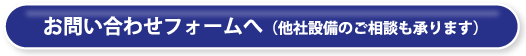

Rotary Kiln (Single-Tube/Multi-Tube)

Equipped with newly-developed technologies optimized for resource recycling processes, etc., this rotary kiln is the next step in the continuous evolution of Chugai Ro’s world-class thermal technology,

and contributes to our customers’ efforts to develop functional materials and achieve zero emissions.

Equipment Features

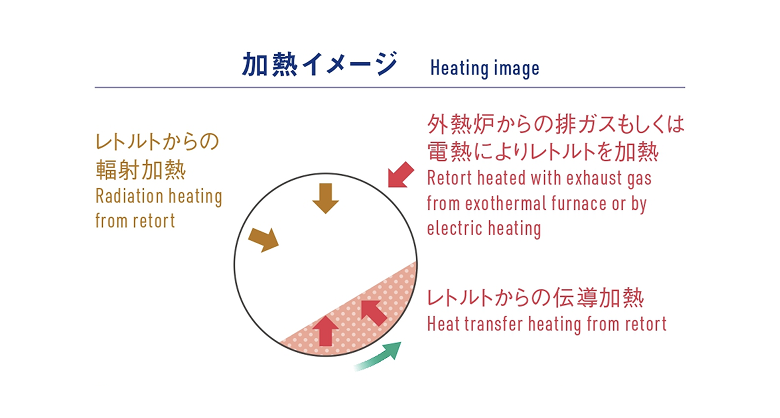

- 1.Heating technology with gentle rotation and agitation

・Temperature and atmosphere contact unevenness has been eliminated, resulting in uniform heating inside the furnace. - 2.Compatible with all atmospheres

・Compatible with all kinds of atmospheres such as air, non-oxidizing, hydrogen (100%), and steam, etc. - 3.Max. temperature 1,100 °C

・Use is possible in a wide range of temperatures, from low-temperature to high-temperature firing, based on the selected retort. - 4.Fine temperature program setting possible

・Heat treatment can be performed under various conditions by specifying temperature rise/fall program settings.

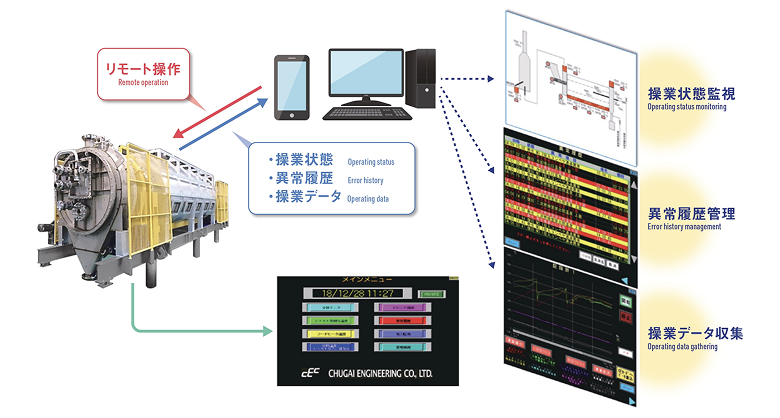

・Furthermore, the use of IoT technology allows remote monitoring and setting. - 5.Fully equipped with automatic operation systems

・Productivity improvements are achieved with automatic continuous and semi-continuous operation systems. - 6.Comprehensive powdered material heating plant

・Can be delivered as an integrated plant capable of handling raw material stock to finished products.

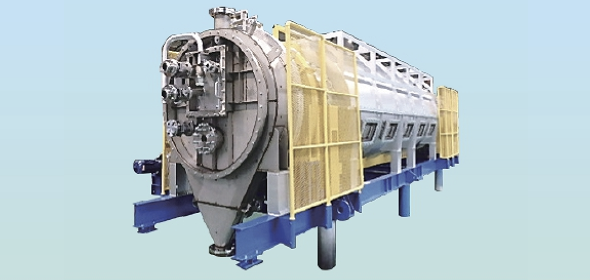

Use

In addition to the firing and calcination of all kinds of powdered material, the features of this external heating type rotary kiln can be leveraged to address a wide range of applications such as oxidation, reduction, and decomposition under various atmospheres, as well as catalyst generation and regeneration.

Application

Metal reduction application with atmospheric hydrogen (100%) in furnace

| Retort | 250 A x 5 x 4,600 mmL |

| Treatment capacity | 25 kg / hr |

| Firing temperature | 800 °C |

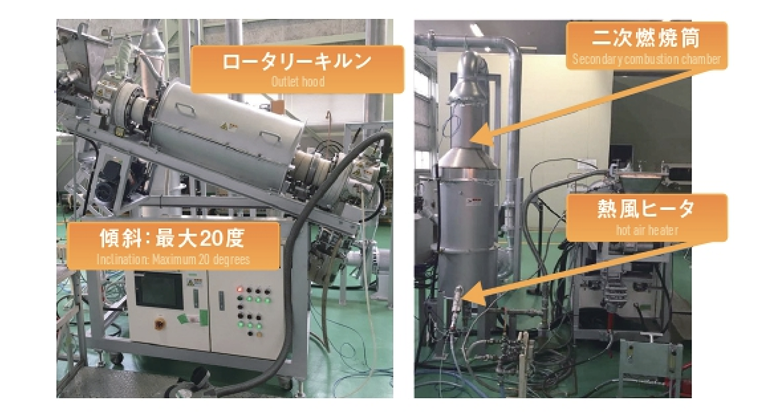

Test application [Rotary kiln test equipment basic specifications]

| Exothermal furnace temp. | max. 1,000 °C ( 3 zones, individually controlled ) |

| Rotation speed | 0 to 5 rpm |

| Tilt angle | selectable ( max. 20 degrees ) |

| Treatment atmosphere | oxidation, nitrogen, steam-activation |

| Exhaust gas treatment | secondary combustion tube( heater type, 800 °C ) |

| Treatment capacity | approx. 1 kg / hr |

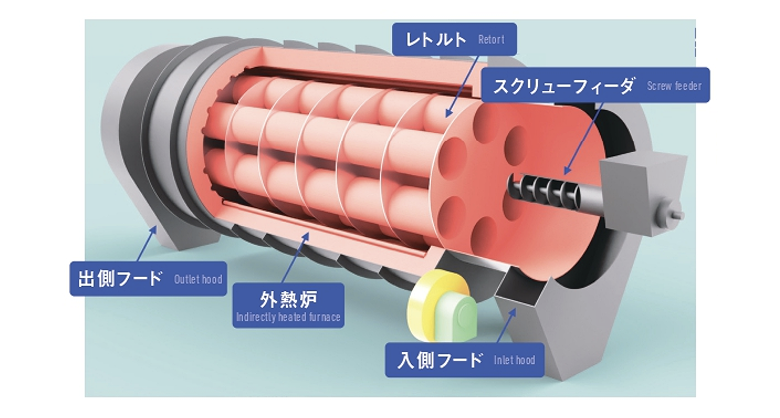

Equipment Structure

A fixed quantity of material fed by a screw feeder is lifted up while being rotated, and is then lowered and agitated near the material angle of repose. This process is repeated, and the material is fed to the exit.

IoT

Support for remote monitoring with IoT technology

Use of IoT technology contributes to “improved safety and stability”, “improved productivity”, and “higher quality”.

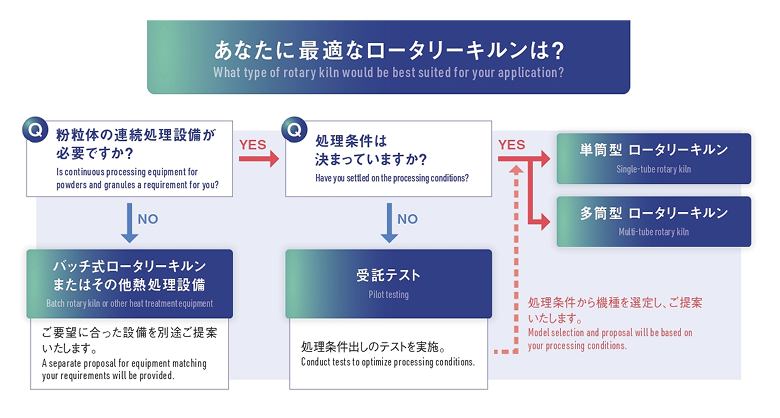

What type of rotary kiln would be best suited for your application?